Dont get me wrong, its not the worst deal but the payment methods have me questioning it. I would want a way to get my money back if it turns out to be scam. $100 to have it now might be worth it to some. Unfortunately, I'll have to order my second action from ARC because I need a short mag now.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coup De Grâce, New Action from American Rifle Company, $899 WOW!

- Thread starter karagias

- Start date

Look again. $899 plus tax plus shipping on ARC site equals what he’s asking. Unless you expect that seller should eat the extra $200.

If you are not trying to be obtuse about it, and are not in a huge hurry and actually want a good deal directly, and don't live in a state where ARC has to collect Sales tax and work out a payment terms discount, you'll be pretty close to that $899 price for new when it lands at your FFL.

I have mine in hand currently.

Not being obtuse. $958 wi/tax, then plus shipping and transfer fee. Not even close to $899 in my hands. I’d have to ask pretty much what that one is selling for in order to break even. Not that I care to sell mine.If you are not trying to be obtuse about it, and are not in a huge hurry and actually want a good deal directly, and don't live in a state where ARC has to collect Sales tax and work out a payment terms discount, you'll be pretty close to that $899 price for new when it lands at your FFL.

I have mine in hand currently.

Need a little advice from those more experienced….

I bought the CDG a few days from when it hit the market. Bought a Xylo chassis as well. Ordered a 6.5CM barrel from PBB. I built it up a few weeks ago and recently received my Forster set of go no-go gauges. Bolt closes butter smooth on both gauges. For a brand new build, I’d rather not order a field gauge as a possible solution. FWIW, I torqued the barrel at 80 ft*lb.

With this being my first bolt action rifle, what would your next step be? Appreciate any advice.

<edit> resolved. PBB took good care of me.

I bought the CDG a few days from when it hit the market. Bought a Xylo chassis as well. Ordered a 6.5CM barrel from PBB. I built it up a few weeks ago and recently received my Forster set of go no-go gauges. Bolt closes butter smooth on both gauges. For a brand new build, I’d rather not order a field gauge as a possible solution. FWIW, I torqued the barrel at 80 ft*lb.

With this being my first bolt action rifle, what would your next step be? Appreciate any advice.

<edit> resolved. PBB took good care of me.

Last edited:

Need a little advice from those more experienced….

I bought the CDG a few days from when it hit the market. Bought a Xylo chassis as well. Ordered a 6.5CM barrel from PBB. I built it up a few weeks ago and recently received my Forster set of go no-go gauges. Bolt closes butter smooth on both gauges. For a brand new build, I’d rather not order a field gauge as a possible solution. FWIW, I torqued the barrel at 80 ft*lb.

With this being my first bolt action rifle, what would your next step be? Appreciate any advice.

Piece of tape on the back of the no-go gauge?

A single piece of well trimmed scotch tape tightens things up, but light-moderate pressure will still close the bolt. i wonder if another 20 ft*lbs on the barrel would give me another thousandth.Piece of tape on the back of the no-go gauge?

Last edited:

A single piece of well trimmed scotch tape tightens things up, but light-moderate pressure will still close the bolt. i wonder if another 20 ft*lbs on the barrel would give me another thousandth.

What's the laser etched marking say for the No Go for length? 1.545?

That is slightly longer than I like mine setup but it should be perfectly safe to shoot. If you are going to reload and you keep your brass with that barrel you will see no issues at all. You will need to adjust your sizing die to fit that chamber.A single piece of well trimmed scotch tape tightens things up, but light-moderate pressure will still close the bolt. i wonder if another 20 ft*lbs on the barrel would give me another thousandth.

Don't swap brass shot in this bolt gun to your AR10. It will only fit this chamber correctly.

Your barrel torque is fine, you can go a little tighter but it isn't going to change anything.

If you are going to shoot factory ammo just go have some fun.

Correct.What's the laser etched marking say for the No Go for length? 1.545?

Planning on shooting Hornady Match for a while. It’s a new hobby for me so it’ll take quite some time before I’m equal to match grade ammo. If I make it through a few barrels and stick with it, then reloading may be on the horizon. I’ll collect my brass no matter.That is slightly longer than I like mine setup but it should be perfectly safe to shoot. If you are going to reload and you keep your brass with that barrel you will see no issues at all. You will need to adjust your sizing die to fit that chamber.

Don't swap brass shot in this bolt gun to your AR10. It will only fit this chamber correctly.

Your barrel torque is fine, you can go a little tighter but it isn't going to change anything.

If you are going to shoot factory ammo just go have some fun.

Scotch tape is around 0.003" (this will vary though, could be as thin as 0.002")

The 1.545 + 2 scotch tape will roughly equate to a field.

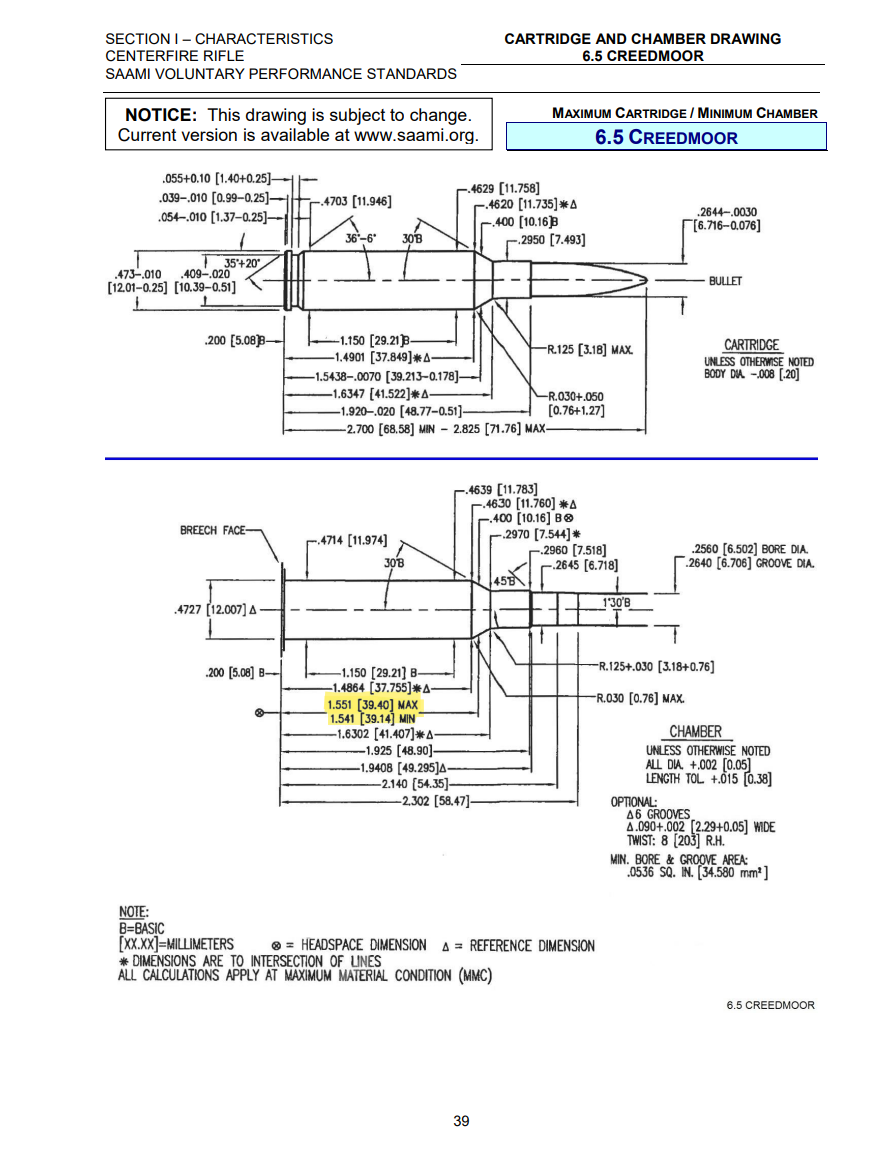

1.545 + 0.003 + 0.003 = 1.551" <- max

Try with 2 layers scotch tape and if it doesn't close, you're likely safe and most likely you'll be around the 1.549" area. However you should contact PBB just to start a line of communication. If they normally to go for min headspace + 0.001", then they're way over and their workmanship is faulty.

There's also a chance that the gauge was machined improperly and is smaller than 1.545".

The 1.545 + 2 scotch tape will roughly equate to a field.

1.545 + 0.003 + 0.003 = 1.551" <- max

Try with 2 layers scotch tape and if it doesn't close, you're likely safe and most likely you'll be around the 1.549" area. However you should contact PBB just to start a line of communication. If they normally to go for min headspace + 0.001", then they're way over and their workmanship is faulty.

There's also a chance that the gauge was machined improperly and is smaller than 1.545".

As suggested above you should call PBB and walk through it with them. It's possible they would want that barrel back.

Thats not how you measure a gauge. The measurement would be from the base of the gauge to the .400” datum on the shoulder.

Adding 20 ft lbs will do nothing by itself. Perhaps a few tighten/ loosen cycles will burnish the barrel shoulder down if its rough. If its smooth, there will be no difference between 30 ft lbs and 200 ft lbs.

Yeah but you could kiss the shoulder with a file.......DON'T DO THAT...cheap joke carry on.Thats not how you measure a gauge. The measurement would be from the base of the gauge to the .400” datum on the shoulder.

Adding 20 ft lbs will do nothing by itself. Perhaps a few tighten/ loosen cycles will burnish the barrel shoulder down if its rough. If its smooth, there will be no difference between 30 ft lbs and 200 ft lbs.

That’s why we ask…. Learning all the time.Thats not how you measure a gauge. The measurement would be from the base of the gauge to the .400” datum on the shoulder.

That would be pretty hard to eyeball, even after finding that point. I’d need a 0.4” hole gauge to move forward with any confidence in results.

So….. assumption is that PBB may have been a little loose in their tolerances at this point.

Yeah but you could kiss the shoulder with a file.......DON'T DO THAT...cheap joke carry on.

Some 1000 grit might be the better tool. But if the consensus is that there’s no danger at this point, I’ll see what PBB says when they call back and move forward with live ammo unless they say otherwise.

No, as subes explained, you need to find the datum plane where that cone diameter is .4" and measure from there to the case base.

They sell one that will get you close enough. Hornady headspace comparator. Get the full set and then get their bullet comparators too.That’s why we ask…. Learning all the time.

That would be pretty hard to eyeball, even after finding that point. I’d need a 0.4” hole gauge to move forward with any confidence in results.

So….. assumption is that PBB may have been a little loose in their tolerances at this point.

My CDG + PVA prefit was the same. One piece of scotch tape on the No-Go gauge demonstrated that the bolt would not close. I was satisfied but also got a field gauge which confirmed my findings with the tape.Bolt closes butter smooth on both gauges. For a brand new build, I’d rather not order a field gauge as a possible solution. FWIW, I torqued the barrel at 80 ft*lb.

With this being my first bolt action rifle, what would your next step be? Appreciate any advice.

Scotch magic tape is .0022" thick. Scotch packing tape is .0058" thick.

Measure your tape and add to gauge. Test your bolt. Also visit a friend or gunsmith who has gauges

Last edited:

Scotch magic tape is .022" thick. Scotch packing tape is .058" thick.

You sure about those numbers?

I have 2 sided tape, which is very thick, that isn't .058" thick ...

He’s missing a decimal placeYou sure about those numbers?

I have 2 sided tape, which is very thick, that isn't .058" thick ...

He’s missing a decimal place

I figured as much. I didn't say it because simply inserting a 0 means he's measuring scotch tape to the Ten-Thousandths... .0022", which seems odd to me.

Yes.I figured as much. I didn't say it because simply inserting a 0 means he's measuring scotch tape to the Ten-Thousandths... .0022", which seems odd to me.

Attachments

I figured as much. I didn't say it because simply inserting a 0 means he's measuring scotch tape to the Ten-Thousandths... .0022", which seems odd to me.

Pardon my confusion, but why would that be odd (measuring to the ten-thousandths that is)?

From a site vendor $900 + ship: https://www.snipershide.com/shooting/threads/arc-coup-de-grace.7186450/What's the current lead time looking like?

Debating between doing this for a NRL Hunter Open Light build or a Tikka UPR for a Factory div build... using my existing supply of AW magazines would be really nice but it just depends on how long it takes to get the action in hand and the rifle assembled

Pardon my confusion, but why would that be odd (measuring to the ten-thousandths that is)?

View attachment 8217740

Now THAT's a gauge

Interesting story here. I once bought a nice calibrated with certificate Starrett inner micrometer. Something just wasn’t adding up as I was taking some baseline measurements. It took me a while to figure it out, but they had printed the numbers in reverse order on the inner barrel like in your picture. I called them and explained the issue. He was skeptical and said that’s not possible, but said “hang on, we have some here on the bench still.” I heard him set the phone down and walk across the shop. Then I hear the “I can’t F’in believe it. Who the F* ran this last batch?” He comes back to the phone and says “Well, I think we’re sending you a replacement now“.Pardon my confusion, but why would that be odd (measuring to the ten-thousandths that is)?

View attachment 8217740

It was just like the old clock joke. It was accurate on the exact digit, and half digit too.

Well, I left a voicemail with PBB and this is the email response I got: “…I'll be sending you a return label to your email. Should be in and out quick once we get it. Apologies for the problems...”. Too bad I can’t just send them the action too (well, I can but that’s $$$ or frustrations).Need a little advice from those more experienced….

I bought the CDG a few days from when it hit the market. Bought a Xylo chassis as well. Ordered a 6.5CM barrel from PBB. I built it up a few weeks ago and recently received my Forster set of go no-go gauges. Bolt closes butter smooth on both gauges. For a brand new build, I’d rather not order a field gauge as a possible solution. FWIW, I torqued the barrel at 80 ft*lb.

With this being my first bolt action rifle, what would your next step be? Appreciate any advice.

Pretty quick and ‘on it’ response so far. I was intending to shoot tomorrow, but can probably hang on for another week or so if required. I’d rather not dirty it up if they are going to replace it or rework the shoulder.

It’s not really anymore money. The difference of less than three pounds weight.Well, I left a voicemail with PBB and this is the email response I got: “…I'll be sending you a return label to your email. Should be in and out quick once we get it. Apologies for the problems...”. Too bad I can’t just send them the action too (well, I can but that’s $$$ or frustrations).

Pretty quick and ‘on it’ response so far. I was intending to shoot tomorrow, but can probably hang on for another week or so if required. I’d rather not dirty it up if they are going to replace it or rework the shoulder.

No.

Shipping a firearm in the US seems to be a pain in the ass though.It’s not really anymore money. The difference of less than three pounds weight.

It’s not really anymore money. The difference of less than three pounds weight.

Agreed, just shipping both would be great if I didn’t have to go pay the FFL fee, and not just shoot over to the ups store that’s 1 mile alway. And of course deal with the process in the return end too.No.

Shipping a firearm in the US seems to be a pain in the ass though.

Hi Sentinel!

Thanks for the info! Would you mind providing a photo of where the interference is located with the folding stock and the knob/handle? I'm working with Jamie from Cadex to try to get my order sorted out and he's very interested in any potential issues that may prevent the CDG from being used with their chassis (since they don't have any to try themselves. Yet.).

How about when the bolt isn’t closed? From here it looks as if the bolt were open, the folder would work.

Will the Tacsport pro x require the fixed handle? What triggers are recommended for the pivoting handle?

Will the Tacsport pro x require the fixed handle? What triggers are recommended for the pivoting handle?

Ok. So what about the second half of my post? What trigger is recommended for people running the pivoting bolt handle

Pretty much everything not specifically listed in the last two bullet points, as long as they don’t have a bolt release.Ok. So what about the second half of my post? What trigger is recommended for people running the pivoting bolt handle

There are even a number of people that have made their TT Diamond and B&As work with the pivoting handle as long as they are not set too light.

I’m not being obtuse here, I’m giving you exactly what information you asked for.

Question for you. Do you have a favorite trigger or brand you use now? Or want to try something else and have something in mind?

The problem comes from setting a trigger to ultra light pull weights and running the bolt aggressively with the pivoting handle. The impact from the cocking piece slamming into the top sear of the trigger can potentially cause the trigger sear to drop or damage the top sear from the constant hard impact (when running the bolt hard). With the fixed handle, the extraction cam surfaces take the brunt of that impact before the cocking piece hits the top sear.Will the Tacsport pro x require the fixed handle? What triggers are recommended for the pivoting handle?

You can potentially mitigate this by adding a little bit of decock on close (opposite of cock/bump on close). Rather than having perfect trigger timing, set the trigger forward slightly 0.002" to 0.005" for decock on close. You can also attempt to switch to a taller top sear that would give more sear/cocking piece surface engagement which would mitigate (to an extent) sear drop but note, it does nothing to lessen cocking piece to trigger sear impact force. Having too tall of a top sear however can cause the top sear to drag on the bolt body or cocking piece.

Last edited:

I don’t have any prior experience with r700 actions or triggers. Everything else I’ve got is AI, TRG or AR15/10. Gonna be using this for NRL Hunter matches and hunting so I’d want something that can handle weather (snow, rain, dirt) well, and probably a two stage that I can adjust to resemble my TRG trigger.Pretty much everything not specifically listed in the last two bullet points, as long as they don’t have a bolt release.

There are even a number of people that have made their TT Diamond and B&As work with the pivoting handle as long as they are not set too light.

I’m not being obtuse here, I’m giving you exactly what information you asked for.

Question for you. Do you have a favorite trigger or brand you use now? Or want to try something else and have something in mind?

I thought folks were reporting good reliability with two stage triggers such as the TT Diamond, BNA TacSport/Pro/X, Timney two stage “light”. I’m running two stage TT Special or whatever the tier below Diamond is. If you want to be able to take the trigger apart for cleaning you want a BNA.I don’t have any prior experience with r700 actions or triggers. Everything else I’ve got is AI, TRG or AR15/10. Gonna be using this for NRL Hunter matches and hunting so I’d want something that can handle weather (snow, rain, dirt) well, and probably a two stage that I can adjust to resemble my TRG trigger.

Nothing is like a TRG trigger, nothing.

I haven't had any issues with a couple of Bix Tacsports on an Archimedes and also on CDG (both have pivoting bolt handles.) Both triggers are set to about 1# 10oz, evenly split between the first and second stage. That means it's the equivalent of a single stage Bix set at 13 oz (the first stage on a 2 stage Bix is just a spring controlling free rotation of the trigger shoe until the trigger shoe contacts the sear lever, so it doesn't factor into the second stage sear weight.)

CDG can use any height sear with a Bix Tacsport / Tacsport pro, but the default medium sear that ships with the trigger is dead in the middle of the acceptable sear engagement range per the table on Bullet Central's website and is the best match to the CDG.

CDG can use any height sear with a Bix Tacsport / Tacsport pro, but the default medium sear that ships with the trigger is dead in the middle of the acceptable sear engagement range per the table on Bullet Central's website and is the best match to the CDG.

Sigh --- didnt see this when I ordered ... am a Tubb shooter.

Good to know! The Tacsport pro x has been highly recommended to me from a couple close friends but I wanted to make sure I wasn’t going to damage anything.I haven't had any issues with a couple of Bix Tacsports on an Archimedes and also on CDG (both have pivoting bolt handles.) Both triggers are set to about 1# 10oz, evenly split between the first and second stage. That means it's the equivalent of a single stage Bix set at 13 oz (the first stage on a 2 stage Bix is just a spring controlling free rotation of the trigger shoe until the trigger shoe contacts the sear lever, so it doesn't factor into the second stage sear weight.)

CDG can use any height sear with a Bix Tacsport / Tacsport pro, but the default medium sear that ships with the trigger is dead in the middle of the acceptable sear engagement range per the table on Bullet Central's website and is the best match to the CDG.

You’d think something would come close but it really is the nicest trigger I’ve ever used.I thought folks were reporting good reliability with two stage triggers such as the TT Diamond, BNA TacSport/Pro/X, Timney two stage “light”. I’m running two stage TT Special or whatever the tier below Diamond is. If you want to be able to take the trigger apart for cleaning you want a BNA.

Nothing is like a TRG trigger, nothing.

My friend, @GBMaryland, who owns TRG's also, thinks the Timney 700, 2 stage "Light" feels much better in the CDG than TT 2 stage that he has tried. He actually VERY much likes the Timney in the CDG. Not a trigger we often hear about on the Hide but they have been making high qual aftermarket triggers for a very long time.

YMMV

YMMV

Guy who timed his trigger is a magician.My friend, @GBMaryland, who owns TRG's also, thinks the Timney 700, 2 stage "Light" feels much better in the CDG than TT 2 stage that he has tried. He actually VERY much likes the Timney in the CDG. Not a trigger we often hear about on the Hide but they have been making high qual aftermarket triggers for a very long time.

YMMV

You mean the guy who timed it and then couldn't resist fucking with it more and messed it up again? That guy? ;-) hahaGuy who timed his trigger is a magician.

Similar threads

- Replies

- 12

- Views

- 1K

Left Hand Sale

WTS/SOLD: WTT ARC Coup De Grace LA

- Replies

- 3

- Views

- 597

- Replies

- 5

- Views

- 802

Left Hand Sale

ARC Coup De Grace LA, Lapua bolt face

- Replies

- 6

- Views

- 733