Yes

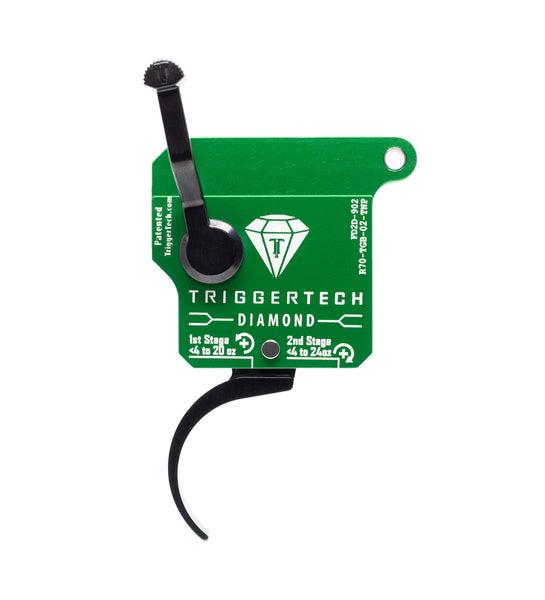

Rem 700 Two-Stage

Our Remington 700 Two-Stage triggers were developed with the same unmatched zero-creep break, tactile pull weight adjustment (on both stages), rugged design, and no compromise engineering. Our focus on safety led us to develop the first Rem 700 trigger with four points of safety. This is a new...triggertech.com

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Coup De Grâce, New Action from American Rifle Company, $899 WOW!

- Thread starter karagias

- Start date

Yes, I corrected my post within seconds of initially making it. I missed the Lefty part and thought he was just asking about TT 2 stage in Special vice Diamond.

I can see orders being prioritized via Date

Configuration

FFL info received

Configuration

FFL info received

Freedom From The Crown Sale 2022

For those who still need a barrel, or who want another one already, our annual Freedom From The Crown sale is live. It's a rough equivalent of the "free brake" GB we did back in February for the CDG's

Sale code is "FFTC2023"

It’s a damn good deal. I think I spent around $680 after you include tax and shipping and all that stuff.Freedom From The Crown Sale 2022

patriotvalleyarms.com

For those who still need a barrel, or who want another one already, our annual Freedom From The Crown sale is live. It's a rough equivalent of the "free brake" GB we did back in February for the CDG's

Sale code is "FFTC2023"

Yeah, i got a jet blast with that deal then decided to go TBAC can instead and now dont know what to do with the unused jetblast i got...It’s a damn good deal. I think I spent around $680 after you include tax and shipping and all that stuff.

Those brakes are really good, so I’m sure you can find someone to take it off your hands. I got the jet4Yeah, i got a jet blast with that deal then decided to go TBAC can instead and now dont know what to do with the unused jetblast i got...

E

Well, if anyone wants one for trade or a discount...Those brakes are really good, so I’m sure you can find someone to take it off your hands. I got the jet4

I'd hang on to it. If you don't have at least one spare brake

Thanks! Just placed an order for a 7PRC barrel for my CDG!Freedom From The Crown Sale 2022

patriotvalleyarms.com

For those who still need a barrel, or who want another one already, our annual Freedom From The Crown sale is live. It's a rough equivalent of the "free brake" GB we did back in February for the CDG's

Sale code is "FFTC2023"

Thanks! Just ordered!!Freedom From The Crown Sale 2022

patriotvalleyarms.com

For those who still need a barrel, or who want another one already, our annual Freedom From The Crown sale is live. It's a rough equivalent of the "free brake" GB we did back in February for the CDG's

Sale code is "FFTC2023"

Damn kicking myself for not waiting and getting the carbon barrel I really wanted. Next time I shall be more knowledgeable!!!Freedom From The Crown Sale 2022

patriotvalleyarms.com

For those who still need a barrel, or who want another one already, our annual Freedom From The Crown sale is live. It's a rough equivalent of the "free brake" GB we did back in February for the CDG's

Sale code is "FFTC2023"

Also, my 6 Creedmoor that just came home looks great!!

Won’t let me add barrel to cartFreedom From The Crown Sale 2022

patriotvalleyarms.com

For those who still need a barrel, or who want another one already, our annual Freedom From The Crown sale is live. It's a rough equivalent of the "free brake" GB we did back in February for the CDG's

Sale code is "FFTC2023"

Did you choose fluting vs none? That was a problem earlier.Won’t let me add barrel to cart

No flutesDid you choose fluting vs none? That was a problem earlier.

I meant, did you check the box for flutes or did you choose none? In the last page or so, it was indicated that you actually have to choose in order to complete your order.No flutes

I meant, did you check the box for flutes or did you choose none? In the last page or so, it was indicated that you actually have to choose in order to complete your order.

I have to say, after taking some time to comb through this action, it absolutely punches above its $900 weight class.

It felt a little draggy on bolt open and close, without a trigger, so I thought perhaps the striker had a burr on it in the area of the shroud. When I took the firing assembly out I wanted to see how the bolt operation felt without any tension and, wow! The bolt will close under its own weight and open effortless and feels buttery smooth.

The striker/cocking piece didn’t have any burrs on it, but what I found was a slightly tight interface between bolt shroud and bolt body. I reinserted the shroud into the bolt body with some Autosol metal polish and lapped the two together. Night and day difference. I don’t recommend it for anyone to just do, and I’m sure I only accelerated what would have happened over hundreds or thousands of cycles, and I assume all responsibility, but wow. I’m a machinist and a tinkerer. It’s in my nature.

Did I mention wow?

Also, I have my hangar setup to have .005” of cock on close and .256” of pin fall. Feels great and I’m sure ignition won’t be an issue.

It felt a little draggy on bolt open and close, without a trigger, so I thought perhaps the striker had a burr on it in the area of the shroud. When I took the firing assembly out I wanted to see how the bolt operation felt without any tension and, wow! The bolt will close under its own weight and open effortless and feels buttery smooth.

The striker/cocking piece didn’t have any burrs on it, but what I found was a slightly tight interface between bolt shroud and bolt body. I reinserted the shroud into the bolt body with some Autosol metal polish and lapped the two together. Night and day difference. I don’t recommend it for anyone to just do, and I’m sure I only accelerated what would have happened over hundreds or thousands of cycles, and I assume all responsibility, but wow. I’m a machinist and a tinkerer. It’s in my nature.

Did I mention wow?

Also, I have my hangar setup to have .005” of cock on close and .256” of pin fall. Feels great and I’m sure ignition won’t be an issue.

Last edited:

Not as extreme as what you did, but I sprayed my bolt and inside of the action down with Hornady One Shot Gun Cleaner and that alone made a huge difference in the smooth running of the bolt. The more you cycle it the better it's going to get too.I have to say, after taking some time to comb through this action, it absolutely punches above its $900 weight class.

It felt a little draggy on bolt open and close, without a trigger, so I thought perhaps the striker had a burr on it in the area of the shroud. When I took the firing assembly out I wanted to see how the bolt operation felt without any tension and, wow! The bolt will close under its own weight and open effortless and feels buttery smooth.

The striker/cocking piece didn’t have any burrs on it, but what I found was a slightly tight interface between bolt shroud and bolt body. I reinserted the shroud into the bolt body with some Autosol metal polish and lapped the two together. Night and day difference. I don’t recommend it for anyone to just do, and I’m sure I only accelerated what would have happened over hundreds or thousands of cycles, and I assume all responsibility, but wow. I’m a machinist and a tinkerer. It’s in my nature.

Did I mention wow?

View attachment 8175394

You are also correct in stating that the bolt is draggy without a trigger in it. A properly adjusted trigger made a big difference.

What trigger are you running?I have to say, after taking some time to comb through this action, it absolutely punches above its $900 weight class.

It felt a little draggy on bolt open and close, without a trigger, so I thought perhaps the striker had a burr on it in the area of the shroud. When I took the firing assembly out I wanted to see how the bolt operation felt without any tension and, wow! The bolt will close under its own weight and open effortless and feels buttery smooth.

The striker/cocking piece didn’t have any burrs on it, but what I found was a slightly tight interface between bolt shroud and bolt body. I reinserted the shroud into the bolt body with some Autosol metal polish and lapped the two together. Night and day difference. I don’t recommend it for anyone to just do, and I’m sure I only accelerated what would have happened over hundreds or thousands of cycles, and I assume all responsibility, but wow. I’m a machinist and a tinkerer. It’s in my nature.

Did I mention wow?

Also, I have my hangar setup to have .005” of cock on close and .256” of pin fall. Feels great and I’m sure ignition won’t be an issue.

View attachment 8175394

TT Diamond 2 stage.What trigger are you running?

So the trigger causes it to be draggy, if not properly adjusted? Or do you mean in general? It causes that issue without having fired a cartridge if inappropriately adjusted?

I’m definitely noticing that the action is a little tight when I fire a cartridge and go to cycle the bolt… so I’m just assuming it needs to break in.

I’m definitely noticing that the action is a little tight when I fire a cartridge and go to cycle the bolt… so I’m just assuming it needs to break in.

No, the drag was coming from a bit of friction between the bolt body and shroud.So the trigger causes it to be draggy, if not properly adjusted? Or do you mean in general? It causes that issue without having fired a cartridge if inappropriately adjusted?

I’m definitely noticing that the action is a little tight when I fire a cartridge and go to cycle the bolt… so I’m just assuming it needs to break in.

Nitriding is surface treatment that hardens to a certain depth, rather than a coating that builds up. The black colour that forms is oxidation. There could be a slight buildup of that oxidation in the area of .0002”-.0003”. I have effectively polished that oxidation off.

About to order a PVA barrel in 6.5CM, 24"

Hoping to do mostly bench shooting as just getting into bolt actions. Maybe PRS eventually.

Debating between medium palma and marksman contours. Thoughts? Or full send with heavy palma vs MTU / M24

Hoping to do mostly bench shooting as just getting into bolt actions. Maybe PRS eventually.

Debating between medium palma and marksman contours. Thoughts? Or full send with heavy palma vs MTU / M24

Last edited:

I like my MTU from them. I chambered my first barrel as a 6 GT in a straight taper 1.20". realized I need to to back and bench the muzzle because of how the Tbac can and mount interface.

All that to say that I've never had problems with contoured barrels. MTU is plenty thicc

All that to say that I've never had problems with contoured barrels. MTU is plenty thicc

I like my MTU from them. I chambered my first barrel as a 6 GT in a straight taper 1.20". realized I need to to back and bench the muzzle because of how the Tbac can and mount interface.

All that to say that I've never had problems with contoured barrels. MTU is plenty thicc

Need to what?

Last edited:

Sorry didn't really make sense. My wife was talking to me haha.Need to what?

I need to bench the shoulder so that my can won't hit it.

There's bigger things to gripe about. I'm not a machinist, just learning how to work on barrels.I’ve never heard the term, “bench the shoulder”.

Just grabbed my 2 other Tbac CB mounts and the other Rusty Nut CB. You're right. So kinda a moot point.No contact on mine . I suppose you could step the shoulder. Maybe has to do with the Rusy Nut CB

Pardon my ignorance, whats a rusty nut cb? I have a tbac cb break on the way...Just grabbed my 2 other Tbac CB mounts and the other Rusty Nut CB. You're right. So kinda a moot point.

Pardon my ignorance, whats a rusty nut cb? I have a tbac cb break on the way...

Muzzle Brake - Single Chamber Suppressor Mount (Thunder Beast Compatib

These are raw, heated treated brakes! Our single chamber muzzle brakes are precision machined out of 17-4 stainless steel. Weight approximately 2.3oz 1.5" Long 5/8 - 24 has .30 caliber bore 1/2 - 28 has .223 caliber bore .950 - 24 external threads with 20 degree taper - compatible with TBAC "CB...

rustynutsdesigns.com

rustynutsdesigns.com

Thanks

Muzzle Brake - Single Chamber Suppressor Mount (Thunder Beast Compatib

These are raw, heated treated brakes! Our single chamber muzzle brakes are precision machined out of 17-4 stainless steel. Weight approximately 2.3oz 1.5" Long 5/8 - 24 has .30 caliber bore 1/2 - 28 has .223 caliber bore .950 - 24 external threads with 20 degree taper - compatible with TBAC "CB...rustynutsdesigns.com

The one thing I really like about their CB is that it's 0.020" smaller so the can doesn't bind on the carbon build up.Pardon my ignorance, whats a rusty nut cb? I have a tbac cb break on the way...

I will tell you flat out that it is highly important that all the dimensions are flawless.

I ran into an issue last year we’re rather than using CB mounts I was using the area 419 adapter system, which removes the need for the CB mounts… and they had a run that were slightly out of tolerance (think thousands) and that was enough to cause a baffle strike on the end cap of my ultra9.

Always use an alignment rod to verify nothing is going to hit your suppressor… especially with aftermarket parts.

I ran into an issue last year we’re rather than using CB mounts I was using the area 419 adapter system, which removes the need for the CB mounts… and they had a run that were slightly out of tolerance (think thousands) and that was enough to cause a baffle strike on the end cap of my ultra9.

Always use an alignment rod to verify nothing is going to hit your suppressor… especially with aftermarket parts.

Last edited:

Don't feed the troll please , it makes him happy .There's bigger things to gripe about. I'm not a machinist, just learning how to work on barrels.

I dont know what he meant by it either.No gripes. Just confused.

Im assuming the term he is looking for is turn down.

For what?I dont know what he meant by it either.

Im assuming the term he is looking for is turn down.

Similar threads

- Replies

- 12

- Views

- 1K

Left Hand Sale

WTS/SOLD: WTT ARC Coup De Grace LA

- Replies

- 3

- Views

- 599

- Replies

- 5

- Views

- 805

Left Hand Sale

ARC Coup De Grace LA, Lapua bolt face

- Replies

- 6

- Views

- 735