A different approach...

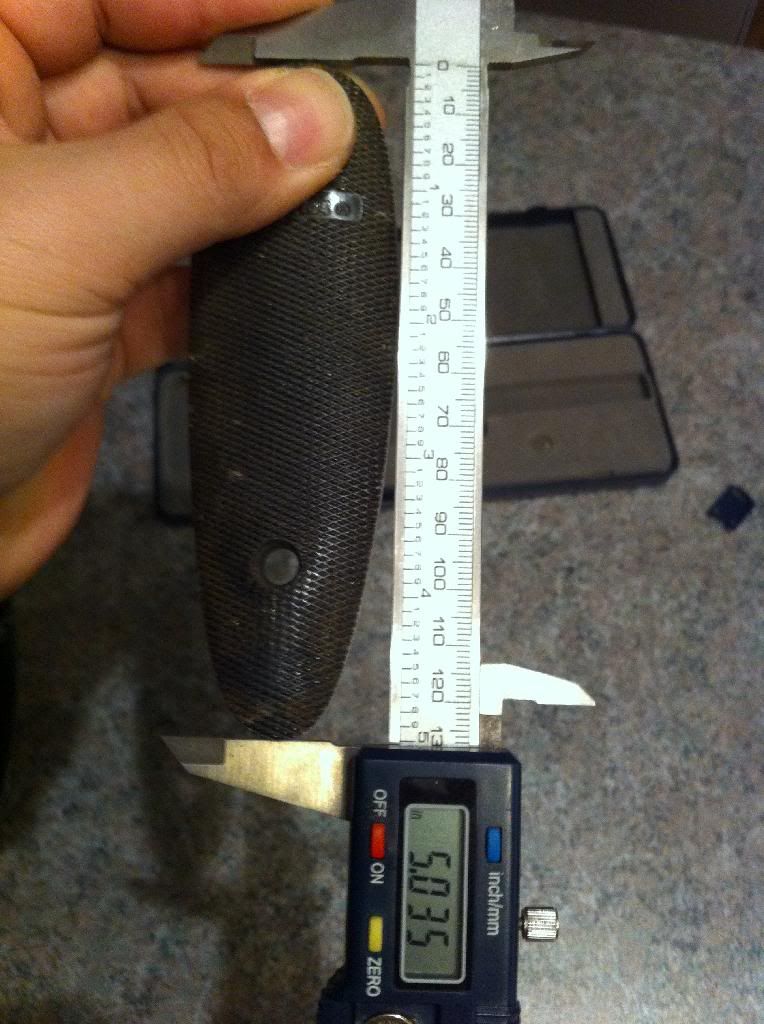

I need for some member to measure (as exactly as possible) the length of the 16601 butt plate and post it.

[I'd do it myself, except for the fact that I put mine back in storage. ]

]

Thanks!

I need for some member to measure (as exactly as possible) the length of the 16601 butt plate and post it.

[I'd do it myself, except for the fact that I put mine back in storage.

Thanks!