I have had the rifle for about 15 years and have used it for hunting, but have since tired of it and looking for a project. This looks like it would be a cool way to spice it up.It would absolutely be a great candidate for an M40 build or even M40a1 if you wanted to go that route as well.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M40 Build Guide

- Thread starter ncoutdoorsman

- Start date

-

- Tags

- m40

D

Deleted member 10043

Guest

So I am lost but I have a few questions I have a old six digit 700 with the first three digits being 148XXX and square safety and double sear. Would this be a perfect candidate for this type of build?

Oh, yes. http://culpeper.x10.mx/M-40sniper.pdf

If the M40 is the way you want to go this thread has a ton of information in it. Also if you wanted to do more research you should definitely get Peter Senich book called the "One Round War USMC Scout Snipers in Vietnam." It has a wealth of information about the M40, M70, and M40a1. Let us know if we can be of any help.

The 'square' safety thumb lever was rounded-off by Remington somewhere late in 69. So it makes sense that these 2nd gen rifles have the round lever. Any M40 built or refurb after the cut-off date should have a round lever.

Just a footnote to MescaBug's post, the 1,000-Remington 2006 Limited Edition SSA actions were all produced with a round safety lever.

Why are these Protecto cases so hard to find. I mean they were manufacturing them up to about 10 years ago.

There's a natural law, that I'm sure explains why, but this is just the kind of item, that you stumble across, when you're not looking and find somewhere you'd least expect to see one. It's just the way of things.

After reading about a member scoring one in a pawn shop, I now ask the dealers if they have any 'hard rifle cases,' every time I'm in one.

A blind squirrel finds a nut, only because he's looking for one. Good luck!!

Last edited:

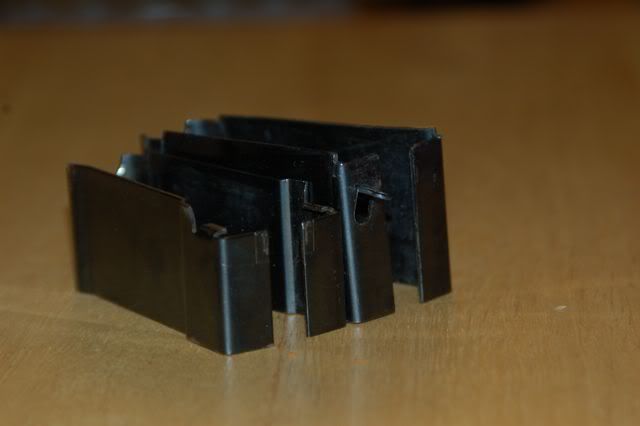

Knocked off the cheap looking texture paint, polished out the aluminum (it's a very cheap alloy, mind you) and anodized it black (as best to could...it's really, really a garbage alloy) and polished with beeswax/lanolin. It went into the sulfuric acid electrolyte shiny, but all the impure metals mixed in dulled out. I have to imagine there is some zinc in there. No ferrous metals, though.

If I would have known, I would have just gloss Duracoated it. No matter, the ano is a much better protective layer.

If I would have known, I would have just gloss Duracoated it. No matter, the ano is a much better protective layer.

Last edited:

So I am lost but I have a few questions I have a old six digit 700 with the first three digits being 148XXX and square safety and double sear. Would this be a perfect candidate for this type of build?

Yes, but that serial number is too early for a 'correct' M40. Just so know, they start at 168XXX.

But having the dual-sear and square safety, its an excellent candidate.

Pillar bedding it. That stock needed a lot of work. Barrel channel had ridges, whole thing had to be contoured. Holes were off too.

Sent from my SCH-I535 using Tapatalk

Trigger guard area. Not a bad stock, though.

stock looks good

Sent from my SCH-I535 using Tapatalk

I see that the receiver's bottom ledge of the ejection port is proud of the stock, are the receiver screws tighten downed already? If so, will you be lowering the receiver into the stock to make the receiver and the stock surface a little more flush?

Nice rifle Toki!

Looking back at some pictures of early M40 with the green scope, I am tempted to have my scope anodized black satin (2nd gen) instead. The original finish and patina is so hard to get right. Satin black is a lot more forgiving.

One thing that's often overlooked is the sling. Not a critical item you might say, but all M40 were issued with a sling.

I didnt read back through the entire thread, but IIRC, both the canvas-cotton type and nylon slings were used. Pre-69 was canvas. I think we can agree that both types are correct. If for any reason, one lost its sling, a nylon type might have been issues as a replacement.

For those interested, I have a few era-correct nylon slings in stock. Some new, some have seen action. They have the correct parkerized buckles.

PM for details.

Looking back at some pictures of early M40 with the green scope, I am tempted to have my scope anodized black satin (2nd gen) instead. The original finish and patina is so hard to get right. Satin black is a lot more forgiving.

One thing that's often overlooked is the sling. Not a critical item you might say, but all M40 were issued with a sling.

I didnt read back through the entire thread, but IIRC, both the canvas-cotton type and nylon slings were used. Pre-69 was canvas. I think we can agree that both types are correct. If for any reason, one lost its sling, a nylon type might have been issues as a replacement.

For those interested, I have a few era-correct nylon slings in stock. Some new, some have seen action. They have the correct parkerized buckles.

PM for details.

Yeah, got 1/2 dozen canvas slings from my Garands. Also have a

black satin gen2. Need to order swivels. Just installed pillars last night and bedded it this am.

I actually have a pretty good repop sling I bought at LRB the last time I was there.

Sent from my SCH-I535 using Tapatalk

black satin gen2. Need to order swivels. Just installed pillars last night and bedded it this am.

I actually have a pretty good repop sling I bought at LRB the last time I was there.

Sent from my SCH-I535 using Tapatalk

Last edited:

D

Deleted member 10043

Guest

That scope is serialized numbered for the M40 SSA. It's a sad fact that they only go with those rifles. The trick is to get them to sell you the serial number on the rifle to match the scope's. The Badger mounts are a true replica of the M40 mounts and rings though. The history behind the scope is that the color wasn't exactly correct and by the time all was said and done the rifles were sold without the scope, mounts and rings as originally hoped for.

stock looks good

I see that the receiver's bottom ledge of the ejection port is proud of the stock, are the receiver screws tighten downed already? If so, will you be lowering the receiver into the stock to make the receiver and the stock surface a little more flush?

Yeah, alot of problems with getting this stock to fit. I've got the receive down a bit lower now, but the floor plate cut out was about 1/16" off to the left, and the fore end/barrel channel is a bit off. Been sanding and carving for days, had to pillar bed.

Yeah, alot of problems with getting this stock to fit. I've got the receive down a bit lower now, but the floor plate cut out was about 1/16" off to the left, and the fore end/barrel channel is a bit off. Been sanding and carving for days, had to pillar bed.

You're really invested, in this stock. Pre-inlets don't (shouldn't, may be a better word) require near this much work. You're way past 5%- as in; out the back door, through the yard, over the back fence, cut through the field, wade across the creek, bully through the hedgerow, march up and over the nearest hill and taking a seat on a cross-country bus... that kind of 'way past.'

I'd call the maker, demand a new (and thoroughly checked-out) replacement (just for the aggravation,) and then... take the first one and lay it on the table of the nearest band saw and make tomato stakes out of it. You'll feel better about the whole experience.

Recognize this butt plate... ?

Of course you do, except this one is on an original Remington 740.

I think they used this same butt plate and screws on the early 742's also. I just wanted to identify the proper screws (and a source,) for this butt plate.

Of course you do, except this one is on an original Remington 740.

I think they used this same butt plate and screws on the early 742's also. I just wanted to identify the proper screws (and a source,) for this butt plate.

Last edited:

D

Deleted member 10043

Guest

Iron Brigade Armory has original butt plates. Iron Brigade Armory

except they're $90!

I got one on eBay for $11 shipped.

The butt plate is fairly easy to find (reasonable, that may be another matter,) it's identifying the proper screws that I was interested in. The wrong screws, i.e. Mod. 721/722, may hold the plate, in place, but they are ill-fitting and look like crap. I don't know if Remington made these screws for a certain period of time and/or for a variety of models during that period, but I do know that both the plate and the screws, for it, are consistent with the Mod. 740 and maybe the 742, as well.

Rob is sending me another one... I have a quite a number of hours in this one having relieved it, re-inletted it, pillar and bedded it.

On a good note, took the rifle out today. Took it through a break in. Shot the following:

1. Hornady 168, loaded with 41.5 grains 4895, 2.81 col. Shot sub MOA .75 @ 100 yards.

2. SMK 175s, (M118LR copies) loaded 42 grains of 4064, 2.82 col, could not get better than 2-3" groups @ 100 yds.

3. M80, mixed cases resized for M14 by a reputable brass guy. I could not get a single round to even chamber. I know the col on these are also well within spec. Bolt would not close.

I checked the headspace on the rifle when I bought it. All within spec. Closes on .308 go, open on no go. If anything, I though I would have had issues with the M118LR due to the bullet ogive.

Here are some blurry, crappy pics....

Stock didn't get the exact finish type I wanted, so I'm doing a couple of coats on BLO on top of the Raw Tung. I'm also going to finish it up with Tom's 1/3 mix. The wood is soooo dry it just soaked up so many coats. Bedding and adjusting the inletting of the stock AFTER I started finishing it didn't help either, so I need to do a bit more finishing work on it. I don't know. I may strip it all down again and start fresh.

First install attempt... Receiver way too proud of stock. It's flush now.

On a good note, took the rifle out today. Took it through a break in. Shot the following:

1. Hornady 168, loaded with 41.5 grains 4895, 2.81 col. Shot sub MOA .75 @ 100 yards.

2. SMK 175s, (M118LR copies) loaded 42 grains of 4064, 2.82 col, could not get better than 2-3" groups @ 100 yds.

3. M80, mixed cases resized for M14 by a reputable brass guy. I could not get a single round to even chamber. I know the col on these are also well within spec. Bolt would not close.

I checked the headspace on the rifle when I bought it. All within spec. Closes on .308 go, open on no go. If anything, I though I would have had issues with the M118LR due to the bullet ogive.

Here are some blurry, crappy pics....

Stock didn't get the exact finish type I wanted, so I'm doing a couple of coats on BLO on top of the Raw Tung. I'm also going to finish it up with Tom's 1/3 mix. The wood is soooo dry it just soaked up so many coats. Bedding and adjusting the inletting of the stock AFTER I started finishing it didn't help either, so I need to do a bit more finishing work on it. I don't know. I may strip it all down again and start fresh.

First install attempt... Receiver way too proud of stock. It's flush now.

Last edited:

I bought butt plate screws from Brownells. I also got slot headed receiver screws too. Had to cut them down and reblue them.

I hear that a lot of guys use Wichita swivels on their M40 clones. I didn't think that Wichita started making their swivels until the 70's. I've seen a picture, in Senich's book, of an original M40 with what looks like Remington 513T type swivels installed. The 513T swivels that I have are 1&1/2 ins. wide (inside). On the early M40's, were the wood screw type used on both the front and rear? Were they 1&1/4 or 1&1/2 in. ?

Thanks, Greg V

If anyone is interested.....

Sarco and Numrich have the Remington 513T swivels for $10 a piece.

Wichita Arms has the Wichitas for $25 + $5 shipping a piece. Just fill out the contact form on the website and Tim McNally will get back to you. I think Iron Brigade charges substantially more for them.

Last edited:

Hey guys here is a video I got of an authentic M40 while at the NRA Museum last week. Sorry for the music, I figured it was better than my mouth breathing

https://www.youtube.com/watch?v=8C4mwUg1IPI

https://www.youtube.com/watch?v=8C4mwUg1IPI

D

Deleted member 10043

Guest

Looks like an M700, go figure. That be it. Notice the burl in the middle of stock. Marines didn't care about aesthetics that much. It just needed to work. They quickly figured out it was not up to the rigors of humping it in the bush. The next generation was upgraded to a synthetic stock as we all know. Eventually, they got rid of the hunting scope as well. Nevertheless, the M40 has character and character counts.

BTW, that video was an important addition to this thread. Nice job!

BTW, that video was an important addition to this thread. Nice job!

Last edited by a moderator:

Looks like an M700, go figure. That be it. Notice the burl in the middle of stock. Marines didn't care about aesthetics that much. It just needed to work. They quickly figured out it was not up to the rigors of humping it in the bush. The next generation was upgraded to a synthetic stock as we all know. Eventually, they got rid of the hunting scope as well. Nevertheless, the M40 has character and character counts.

BTW, that video was an important addition to this thread. Nice job!

Scope is olive colored. Not the OD Green Caswell sells. Interesting...

Beautiful rifle.

Notice how the scope is 'squeezed' between the rings. Kinda odd... I dont see any reason why they would mount it like that.

Thats the patina which is almost impossible to get correct. I dont know if its the gloss black undercoat thats gives that 'purple-ish' tint to it. But after some years and exposure, thats how they turned.

Notice how the scope is 'squeezed' between the rings. Kinda odd... I dont see any reason why they would mount it like that.

Scope is olive colored. Not the OD Green Caswell sells. Interesting...

Thats the patina which is almost impossible to get correct. I dont know if its the gloss black undercoat thats gives that 'purple-ish' tint to it. But after some years and exposure, thats how they turned.

If those were anodized green, there is no gloss black undercoat. When you anodize, you need bare, degreased, desmutted aluminum. You can't ano over existing ano.Beautiful rifle.

Notice how the scope is 'squeezed' between the rings. Kinda odd... I dont see any reason why they would mount it like that.

Thats the patina which is almost impossible to get correct. I dont know if its the gloss black undercoat thats gives that 'purple-ish' tint to it. But after some years and exposure, thats how they turned.

It's a result of the dyes they used back then. It would be great to know what they used. The problem is the dyes have come such a long way since then. I wouldn't be surprised if they used clothing dye, or the dye used for uniforms. Think of the color wheel. Green is blue and yellow, so the blue must break down and leave the yellow (gold) hue. The "patina" is due to the different alloys that Redfield used. If you look at the eyepiece, it has a different finish. This also happens when I've been anodizing. The eyepieces seem to corrode a bit faster, along with the caps and turret housing,

Last edited:

Beautiful rifle.

Notice how the scope is 'squeezed' between the rings. ...

This is a phrase that I'm not familiar with. Would you elaborate, a bit, on that?

Q. Does this M40 look like it has Manganese Parkerizing, or is it just me?

What I meant by that was that the scope is mounted toward the barrel, against the rings. The rear ring is touching the rear eyepiece and the front is touching the turret.

Thanks for the explanation. I am no expert when it comes to scopes!

If those were anodized green, there is no gloss black undercoat. When you anodize, you need bare, degreased, desmutted aluminum. You can't ano over existing ano.

It's a result of the dyes they used back then. It would be great to know what they used. The problem is the dyes have come such a long way since then. I wouldn't be surprised if they used clothing dye, or the dye used for uniforms. Think of the color wheel. Green is blue and yellow, so the blue must break down and leave the yellow (gold) hue. The "patina" is due to the different alloys that Redfield used. If you look at the eyepiece, it has a different finish. This also happens when I've been anodizing. The eyepieces seem to corrode a bit faster, along with the caps and turret housing,

Thanks for the explanation. I am no expert when it comes to scopes!

Beautiful rifle.

Notice how the scope is 'squeezed' between the rings. Kinda odd... I dont see any reason why they would mount it like that.

Thats the patina which is almost impossible to get correct. I dont know if its the gloss black undercoat thats gives that 'purple-ish' tint to it. But after some years and exposure, thats how they turned.

I think it's mounted like that due to operator eye relief...

What I meant by that was that the scope is mounted toward the barrel, against the rings. The rear ring is touching the rear eyepiece and the front is touching the turret.

Thanks for the explanation. Reviewing some of the photos, in this forum and at least one (1) actual VN combat photo, does seem to indicate that it wasn't at all unusual.

The original LOP at 13-3/8" stock specifications (the one-size-fits-all) is just hell on a long armed rifleman. Personally, I'm average, in height (5'-9") but have long arms and am most comfortable with a 13-3/4" to 14-0" LOP. My face is further forward, on a short stock and I have a tendency to 'crawl' a short stock and on my factory stocked rifles, move my scopes up as far as I can. It helps me get a good sight picture and/or keeps the scope's eye piece/ocular lens housing from being planted in my head (depending on the cartridge, of course.)

Another possible factor, given the low ring height, is that it moves the scope's objective bell/objective lens further down the barrel and away from the higher barrel contour near the chamber, lessening any direct contact on recoil impulse.

Other's mileage may differ...

D

Deleted member 10043

Guest

I actually talked to that guy in the middle. He is now a retired union man living in California. Unfortunately, the other two our now dead from natural causes (at least I hope Burdwell is still living). According to Burdwell they are judging distance on a spot over a thousand yards out from their position on the hill. There are enemy at the spot. Actually, they are completely surrounded. It is Khe Sahn. But they are watching a troublesome and occupied spot. The book gives a slightly different description with a John Wayne twist. Earl Breeding (google him, Hill 861A) lived in Roswell is why I sort of was able to contact Burdwell. For me guys like Breeding and Burdwell are like Johnny Unitas is to a Baltimore Colts fan.

It is Khe Sahn. But they are watching a troublesome and occupied spot. The book gives a slightly different description with a John Wayne twist. Earl Breeding (google him, Hill 861A) lived in Roswell is why I sort of was able to contact Burdwell. For me guys like Breeding and Burdwell are like Johnny Unitas is to a Baltimore Colts fan.

Most of the time, we're scrounging around and picking-up parts that are loose and w/out papers.

We've got a photo of a vintage Redfield box...

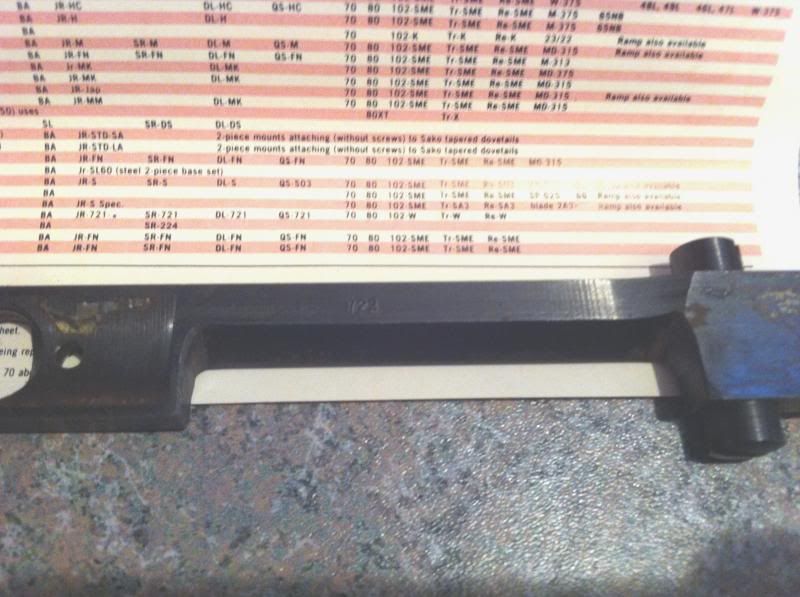

Q's. What does this mount look like and what number did Redfield assign to it?

Thanks!

Most of the time, we're scrounging around and picking-up parts that are loose and w/out papers.

We've got a photo of a vintage Redfield box...

Q's. What does this mount look like and what number did Redfield assign to it?

Thanks!

Thats a 722 base. It is stamped 722, with 'Redfield' and the patent number on the right side. I think I still have the original box with the manual and a parts number listing. I'll try to snap better pics tonite and get the part number from the manual.

Thanks for the explanation. Reviewing some of the photos, in this forum and at least one (1) actual VN combat photo, does seem to indicate that it wasn't at all unusual.

The original LOP at 13-3/8" stock specifications (the one-size-fits-all) is just hell on a long armed rifleman. Personally, I'm average, in height (5'-9") but have long arms and am most comfortable with a 13-3/4" to 14-0" LOP. My face is further forward, on a short stock and I have a tendency to 'crawl' a short stock and on my factory stocked rifles, move my scopes up as far as I can. It helps me get a good sight picture and/or keeps the scope's eye piece/ocular lens housing from being planted in my head (depending on the cartridge, of course.)

Another possible factor, given the low ring height, is that it moves the scope's objective bell/objective lens further down the barrel and away from the higher barrel contour near the chamber, lessening any direct contact on recoil impulse.

Other's mileage may differ...

Just bought the Senich book for my Kindle...

M40 Bolt Shroud... Q.

We've got photos of the M40's short(ened) bolt shroud, but what is the exact length of this 'short' bolt shroud on the M40, measured from the shoulder/flange which butts against the receiver, to the rear edge?

Thanks!

...

One in the middle between 64 original short and newer longer shroud. Cold blued on the end only.

Thanks.

Respectfully,

Dennis

We've got photos of the M40's short(ened) bolt shroud, but what is the exact length of this 'short' bolt shroud on the M40, measured from the shoulder/flange which butts against the receiver, to the rear edge?

Thanks!

Not compatible... The ADL box is taller. If I were you, I would buy a steel floorplate kit from Pacific Tool & Gauge. The early Rem 700 bottom metals is steel, not aluminum. Looks exactly the same.

For those looking for an alternative to parkerizing, Cerakote has a color that is very similar to the green-ish finish on the M40. Its called Tungsten.

I've seen it on a pistol, and it is very close. Of course, its not the same 'texture'. Most tactical gunsmith shops will do Cerakote. Parkerizing is messy... Stuff from the past

Cant get enough of those build threads!

Actually, according to Senichs book, the floor plate metal on the M40 is aluminum, despite claims to it being steel.

Excellent book. Answers a ton a questions.

Actually, according to Senichs book, the floor plate metal on the M40 is aluminium,.........

Excellent book. Answers a ton a questions.

This had been my understanding;- In the mid-late 70's when they were developing a "product improved" m40 and looking to make everything about it "tank like", a steel version of the M700 bottom metal was requested from Remington, however they refused to produce them and hence why Winchesters Model 70 floor plate was eventually adopted for the M40a1.

Yeah it is an excellent book, great depth of detail.

Last edited:

Q. M40 Commemorative Bottom Metal-Floorplate...

Q. Is the M40 Commemorative bottom metal/floorplate group, substandard and/or too light-weight, compared to the 'standard' M700 hardware?

My question originates from reading some 'on-line' comments about the M40 Commemorative Rifle and the 'need' to replace these part(s,) if one was to actually use the rifle; as opposed to just admiring it, from afar, I guess.

Note: This is my first Remington 700 and I've no frame of reference, of my own.

Thanks!

Q. Is the M40 Commemorative bottom metal/floorplate group, substandard and/or too light-weight, compared to the 'standard' M700 hardware?

My question originates from reading some 'on-line' comments about the M40 Commemorative Rifle and the 'need' to replace these part(s,) if one was to actually use the rifle; as opposed to just admiring it, from afar, I guess.

Note: This is my first Remington 700 and I've no frame of reference, of my own.

Thanks!

D

Deleted member 10043

Guest

I have over 3000 rounds down an M40 SSA. (M40 Commemorative). Remington considers it a custom shop job because it is a 40x series rifle and that is a dirty little secret about this rifle. It does have an aluminum floor plate. The accuracy is within original specs.

Response Danny via Email 12/07/2011 06:56 AM

The 40 X series is based off of the 700 action, but this is a 40 X series rifle.

Customer via CSS Email 12/06/2011 07:40 PM

Isn't the Model 40 SSA really a Model 700 and not a Model 40x? Let me

know. Thanks.

On 12/6/11, Remington Information <[email protected]> wrote:

>

Response Danny via Email 12/06/2011 08:44 AM

We do not list part numbers for barrels on the 40 X series. These are Custom Shop rifles and they are the only place to get original barrels. The rifle will need to be sent in to have us replace the barrel.

Customer via CSS Web 12/04/2011 04:57 PM

What is the barrel part number for my Model 40 SSA? Thanks

Last edited by a moderator:

This had been my understanding;- In the mid-late 70's when they were developing a "product improved" m40 and looking to make everything about it "tank like", a steel version of the M700 bottom metal was requested from Remington, however they refused to produce them and hence why Winchesters Model 70 floor plate was eventually adopted for the M40a1.

Yeah it is an excellent book, great depth of detail.

You guys might be right about the aluminum floorplate. I dont have the Senichs book.

I will add something to the part about the M40A1. The Winchester 70 floorplate latch mechanism is outside the trigger guard, which makes it harder to accidentaly engage the mechanism and drops ammo. Apparently, the snipers didnt like the M40 at first, and asked that the M70 floorplate be used on the 'upgraded M40' which became the M40A1.

It has nothing to do with Remington. Most M40A1 were upgraded from M40. They came in the shop with the Remington floorplates. The armorers at Quantico simply tossed away the Remington units, replaced it with Winchester's, and installed it in the already inletted stocks specially prepared and inletted by McMillan.

The Remington contract was to supply the army with a bunch of Rem 700. Was Remington contacted about a steel floorplate? I dont know. And dont think so. Maybe. Do we have a proof of that somewhere? If yes, than we have solid facts to backup the theory about the aluminum floorplate.

Last edited:

Similar threads

- Replies

- 4

- Views

- 488