Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M40 Build Guide

- Thread starter ncoutdoorsman

- Start date

-

- Tags

- m40

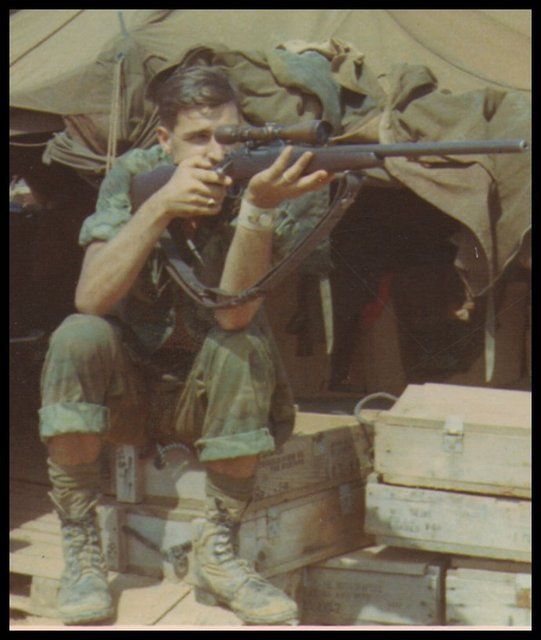

Here's my addition. I hope to get my M40 finished this year. I have all original stock, barrel, scope and mounting hardware.

Great photo. There's definitely some great information fueling discussion, on this forum, of late.

Would definitely like to see some detailed photos of your original stock and barrel/stamps.

The M40 parts nuances... the front sling

In assembling the M40 into a rifle that was acceptable to the USMC, it's obvious that Remington utilized parts that were already in it's manufacturing stream and in some cases, modified and carried over into other models. The 513T sling swivel, with some variation, a prime example.

The 513T Rear Swivel_ 1-1/4" (source: Numrich Gun Parts, SKU: 83350A [post w/wood threads])

An Early REM. 760 Parts Group (source: eBay)

A Remington 721, 722, 725 Swivel Assembly-Front (source: Numrich Gun Parts SKU: 719430 [post w/machine threads & 1" swivel])

Searching the Remington manufacturing stream for sourcing and identifying the correct parts/models, for the M40... opens-up the possibility of finding the correct parts and not wasting your money.

In assembling the M40 into a rifle that was acceptable to the USMC, it's obvious that Remington utilized parts that were already in it's manufacturing stream and in some cases, modified and carried over into other models. The 513T sling swivel, with some variation, a prime example.

The 513T Rear Swivel_ 1-1/4" (source: Numrich Gun Parts, SKU: 83350A [post w/wood threads])

An Early REM. 760 Parts Group (source: eBay)

A Remington 721, 722, 725 Swivel Assembly-Front (source: Numrich Gun Parts SKU: 719430 [post w/machine threads & 1" swivel])

Searching the Remington manufacturing stream for sourcing and identifying the correct parts/models, for the M40... opens-up the possibility of finding the correct parts and not wasting your money.

About the swivels. Do we have any idea as to where we can get the front swivel escutcheon? And what is the thread size/pattern of the swivel/escutcheon?

Must be a Remington part. Wichitas got the contract in 70.

Must be a Remington part. Wichitas got the contract in 70.

About the swivels. Do we have any idea as to where we can get the front swivel escutcheon? And what is the thread size/pattern of the swivel/escutcheon? Must be a Remington part. Wichitas got the contract in 70.

MescaBug,

Not sure about availability of a 'Remington' part, but a 10/32 machine thread is an industry standard, so an Uncle Mike's escutcheon, for instance, will get the job done, but with that Varmit contoured barrel, I'd want something with a bit more surface area.

Something like this:

Source: Rifle Sling Swivel Mount for A Synthetic Hollow Forearm with Curved Backplate | eBay

You could take a grinder to it and make it round, if you'd prefer. Making one out of a spare Uncle Mike's escutcheon and Loctite (Red) a washer to it, would get the job done too.

Leave it outside for a few months

I think I have an extra set that are 'aged' a bit. I used a NOS ring set on my build. But if you prefer the 'distressed' look, I might have what you need.

I'll check tonite and let you know in PM.

I think I have an extra set that are 'aged' a bit. I used a NOS ring set on my build. But if you prefer the 'distressed' look, I might have what you need.

I'll check tonite and let you know in PM.

We've got photos of the M40's short(ened) bolt shroud, but what is the exact length of this 'short' bolt shroud on the M40, measured from the shoulder/flange which butts against the receiver, to the rear edge?

Thanks!

Does anyone have the answer to this question?

totenkopf's Redfield Gen.I photo...

I thought it deserved to be full-sized, for those that keep photo reference files:

Observations:

Notice how some of the parts, i.e., tactical post, optic lens housing retaining ring and set screw in the power knob have a 'polished blue' color?

Q. for totenkpof:

In mint/unissued condition, are the color variations that we see in your photo, actual variations or, just due to photographing the piece?

My question arises from looking at the M40 in the NRA museum, which by all appearances, shows similar variations.

Thanks!

I thought it deserved to be full-sized, for those that keep photo reference files:

Observations:

Notice how some of the parts, i.e., tactical post, optic lens housing retaining ring and set screw in the power knob have a 'polished blue' color?

Q. for totenkpof:

In mint/unissued condition, are the color variations that we see in your photo, actual variations or, just due to photographing the piece?

My question arises from looking at the M40 in the NRA museum, which by all appearances, shows similar variations.

Thanks!

Last edited:

The 'Short' Bolt Shroud...

Culpeper,

Thanks for the reply, and I have to ask, is this on your SSA model?

I'm pretty sure the SSA models retained the standard length bolt shroud and the rounded knob safety, though I may be in error.

Regardless, it's very useful information.

Bolt shroud on mine is .885"

Sent from my C771 using Tapatalk 2

Culpeper,

Thanks for the reply, and I have to ask, is this on your SSA model?

I'm pretty sure the SSA models retained the standard length bolt shroud and the rounded knob safety, though I may be in error.

Regardless, it's very useful information.

I thought it deserved to be full-sized, for those that keep photo reference files:

Observations:

Notice how some of the parts, i.e., tactical post, optic lens housing retaining ring and set screw in the power knob have a 'polished blue' color?

Q. for totenkpof:

In mint/unissued condition, are the color variations that we see in your photo, actual variations or, just due to photographing the piece?

My question arises from looking at the M40 in the NRA museum, which by all appearances, shows similar variations.

Thanks!

Guys, I think I've mentioned this a few times.

Different parts on the scope are made with different aluminum alloys, and each of these alloys have distinct anodic layers that build up. These different layers take up dye differently, And the color breaks down differently, hence the color variation. Similar to how dying your 100% cotton pants and 50/50-cotton/poly jacket will look different when they're dry. Or how an Italian guy will get a better tan than an Irish guy. As far as the power knob and ring, they're usually not anodized as the thumbscrew is STEEL and the retaining ring is just ignored. I've done the ring, but usually ignore it.

Why do they turn goldish? Think of the color wheel. Green is actually made by combining blue and yellow. The anodic layer takes up blue and yellow particles that look green to the eye. When the blue starts to break down(has to do with what the dye was derived from and particle size) rom UV rays (think about those clothes in store displays that get sun bleached) yellow becomes more dominant to the human eye. Now, some anodic layers are better than others (alloy again), so some parts will retain their green particles longer... With gen 1 scopes, the tube itself is an high grade aluminum alloy, hence, it anodizes the best. The scope bell must be stretched more, so there seems to be higher iron or zinc content which does not anodize. Think of a guy with lots of hair, and someone who is thinning. Get it?

Last edited:

Cool. I have two NOS sets. I wonder if liquid sandpaper will take the gloss off.

Sent from my C771 using Tapatalk 2

Rub them with steel wool or bead blast them....

You guys might be right about the aluminum floorplate. I dont have the Senichs book.

I will add something to the part about the M40A1. The Winchester 70 floorplate latch mechanism is outside the trigger guard, which makes it harder to accidentaly engage the mechanism and drops ammo. Apparently, the snipers didnt like the M40 at first, and asked that the M70 floorplate be used on the 'upgraded M40' which became the M40A1.

It has nothing to do with Remington. Most M40A1 were upgraded from M40. They came in the shop with the Remington floorplates. The armorers at Quantico simply tossed away the Remington units, replaced it with Winchester's, and installed it in the already inletted stocks specially prepared and inletted by McMillan.

The Remington contract was to supply the army with a bunch of Rem 700. Was Remington contacted about a steel floorplate? I dont know. And dont think so. Maybe. Do we have a proof of that somewhere? If yes, than we have solid facts to backup the theory about the aluminum floorplate.

A few quotable quotes for you, from one of Peter Senich's books (citing USMC internal reports/evaluations).

(Problems with the M40 system in service)

"......efforts to sustain the system in RVN were centred on..... ...."the adequate supply of spare trigger guards (according to early field reports, the cast aluminium M700 trigger guards were "easily damaged" in combat). pg 238 a "system in transition", The one round war

(Proposed upgrades for the M40 "modified" or "product improved" which eventually turned into the A1)

The features that were considered "major improvements" to the M40 rifle were listed in the following order:........

.........(4) Improved durability through replacing aluminium trigger guards with steel guards [stamped steel trigger guard of the same configuration as the one presently in use].

pg 247 a "system in transition", The one round war

About Remingtons decision not to furnish steel floorplate for the A1, Have definitely read it put a lot more directly than that however haven't found that reference again as yet, will keep looking.

Any of that, proof enough?

Last edited:

I think I was bidding against you but stopped once someone else listed a pair of NOS stil in the wrap and sealed

I think I was bidding against you but stopped once someone else listed a pair of NOS stil in the wrap and sealed

Did they come with a 2x scope and Winchester 94 base? If so then yeah we were bidding against each other!

Last edited:

D

Deleted member 10043

Guest

Barrel Color

#78766a Hex Color Code Schemes, Charts, Palettes, Paints & RGB / CMYK / HSL Conversion

It's in this ballpark of Red 47% Green 46% Blue 42%

#78766a Hex Color Code Schemes, Charts, Palettes, Paints & RGB / CMYK / HSL Conversion

It's in this ballpark of Red 47% Green 46% Blue 42%

Dear M40 Build Guide Thread,

You are the best and worst thing to happen to me.

-Aur0ra145's wallet

Well, it all started with the time old assumption "It would be criminal if I didn't take advantage of the good deal on that 700 Varmint." Followed closely by, "What the hell am I going to do with this?" Naturally I stumbled across this thread for the 300th time and said to myself, "That would be cool. It's beautiful, sexy, vintage and will make hoards of attractive women flock to my yard."

As it sits now, I've got the proper buttplate, and civvy version of a Gen1 scope on the way. I've got an order in with Silver Hill for a stock and should be here in the next couple of weeks. Wichita still has the sling swivel and I'll get that on the way once the stock arrives. According to the e-mails I exchanged with them, they're under new management but still have the swivels. I'll follow up and see if they are still producing them, or just selling off what they still have in stock.

Questions:

1. The front swivel is a Witchita from what I've learned. However, do we have a good idea as to what the rear swivel is? I've seen some people saying it's off a 513, is that the general consensus?

2. I have a sight base that has the look, but isn't period correct. Where do ya'll find the best sources for these?

3. Rings: I haven't had any luck finding any marked 1-64 or 1-66. Is there a good alternate to these, or should I just keep up the search?

4. Slings: Does anyone have a good source for the leather MRT slings?

5. Buttplate Screws: One member said he thinks they're off a 740, can any substantiate that? They do look correct to me and I think the guy is right, just looking for further affirmation.

6. Clipslotting: Who can do this? Is it necessary?

7. Parkerizing: Who can do this? I've seen some people think the green tint of because of the oil they put on these rifles. Would parking the barelled action and dunking it in cosmoline and bombarding it with UV light work? I'm thinking along the lines of how Garands got their green color (maybe.) It might be a long shot, but I talked to a guy who swore by it.

8. Trigger: Will an older style spit sear work on a newer production 700?

9. Sex Appeal: On a scale from 1 to Maggot, where will I fall?

I'm sure I'll more questions later.

cheers

D

Deleted member 10043

Guest

Questions:

1. The front swivel is a Witchita from what I've learned. However, do we have a good idea as to what the rear swivel is? I've seen some people saying it's off a 513, is that the general consensus?

http://www.snipershide.com/shooting...les/53800-m40-build-guide-15.html#post2835799

2. I have a sight base that has the look, but isn't period correct. Where do ya'll find the best sources for these

Redfield still makes the base but a vintage Redfield 511227 is preferable and are common to find on auction sites. BTW, this is the part number for the base in the 1966 Redfield catalog.

3. Rings: I haven't had any luck finding any marked 1-64 or 1-66. Is there a good alternate to these, or should I just keep up the search?

Vintage Redfield 522000 are common. You don't need the ones marked underneath with dates.

4. Slings: Does anyone have a good source for the leather MRT slings?

Garand slings.

5. Buttplate Screws: One member said he thinks they're off a 740, can any substantiate that? They do look correct to me and I think the guy is right, just looking for further affirmation.

The member is correct. If you want screws call Remington custom shop and tell them you want screws for the M40 SSA. They will tell you to send the rifle in but you can inquire about other similar part numbers that will work because you only lost one screw and it seems not practical to send an entire stock in for one screw. Remington didn't eat the cost of creating a special screw for the M40 SSA. I'm sure they used something already in production.

6. Clipslotting: Who can do this? Is it necessary?

It is not necessary. It is either there from the beginning or not.

7. Parkerizing: Who can do this? I've seen some people think the green tint of because of the oil they put on these rifles. Would parking the barelled action and dunking it in cosmoline and bombarding it with UV light work? I'm thinking along the lines of how Garands got their green color (maybe.) It might be a long shot, but I talked to a guy who swore by it.

It's not green tint because of oil or patina wear. It was the original parkerizing and it is a green/gray color. Over time all existing specimens have had oil on the barrel, which changed the original color. My post above was determined from taking a good color photograph of an original and just taking several pixels and seeing what was the color code using image software. It is as close as one can get without an original rifle to take to a paint specialist who will do the same thing with software. Scan the rifle and the software spits out a color code(s). http://www.snipershide.com/shooting...les/53800-m40-build-guide-15.html#post2854570

8. Trigger: Will an older style spit sear work on a newer production 700?

I don't know this one.

9. Sex Appeal: On a scale from 1 to Maggot, where will I fall?

1; It just needs to look like an M40 because it is a cool look. If it shoot 1 moa than it shoots as well too.

1. The front swivel is a Witchita from what I've learned. However, do we have a good idea as to what the rear swivel is? I've seen some people saying it's off a 513, is that the general consensus?

http://www.snipershide.com/shooting...les/53800-m40-build-guide-15.html#post2835799

2. I have a sight base that has the look, but isn't period correct. Where do ya'll find the best sources for these

Redfield still makes the base but a vintage Redfield 511227 is preferable and are common to find on auction sites. BTW, this is the part number for the base in the 1966 Redfield catalog.

3. Rings: I haven't had any luck finding any marked 1-64 or 1-66. Is there a good alternate to these, or should I just keep up the search?

Vintage Redfield 522000 are common. You don't need the ones marked underneath with dates.

4. Slings: Does anyone have a good source for the leather MRT slings?

Garand slings.

5. Buttplate Screws: One member said he thinks they're off a 740, can any substantiate that? They do look correct to me and I think the guy is right, just looking for further affirmation.

The member is correct. If you want screws call Remington custom shop and tell them you want screws for the M40 SSA. They will tell you to send the rifle in but you can inquire about other similar part numbers that will work because you only lost one screw and it seems not practical to send an entire stock in for one screw. Remington didn't eat the cost of creating a special screw for the M40 SSA. I'm sure they used something already in production.

6. Clipslotting: Who can do this? Is it necessary?

It is not necessary. It is either there from the beginning or not.

7. Parkerizing: Who can do this? I've seen some people think the green tint of because of the oil they put on these rifles. Would parking the barelled action and dunking it in cosmoline and bombarding it with UV light work? I'm thinking along the lines of how Garands got their green color (maybe.) It might be a long shot, but I talked to a guy who swore by it.

It's not green tint because of oil or patina wear. It was the original parkerizing and it is a green/gray color. Over time all existing specimens have had oil on the barrel, which changed the original color. My post above was determined from taking a good color photograph of an original and just taking several pixels and seeing what was the color code using image software. It is as close as one can get without an original rifle to take to a paint specialist who will do the same thing with software. Scan the rifle and the software spits out a color code(s). http://www.snipershide.com/shooting...les/53800-m40-build-guide-15.html#post2854570

8. Trigger: Will an older style spit sear work on a newer production 700?

I don't know this one.

9. Sex Appeal: On a scale from 1 to Maggot, where will I fall?

1; It just needs to look like an M40 because it is a cool look. If it shoot 1 moa than it shoots as well too.

Last edited by a moderator:

Patinated rings (mount)... a thought on the topic

What would happen if you put them in a (reloading) tumbler with some fine walnut or corn cob media to soften the high gloss a bit? At least you can stop and examine as you go. Rub them with toothpaste? I think you'd get a 'patinated' look to the existing blued finish versus pitting the metal surface itself.

What would happen if you put them in a (reloading) tumbler with some fine walnut or corn cob media to soften the high gloss a bit? At least you can stop and examine as you go. Rub them with toothpaste? I think you'd get a 'patinated' look to the existing blued finish versus pitting the metal surface itself.

PC Redfield 700SA... and a blind squirrel / Q&A

Current purchase source link (good for ~6 Days)

Remington Model 700 s A Redfield Scope Mount Base w Rings | eBay

Butt plate screws from the Early 742's will also fit. Look for the early/original Remington 'deep-well' Phillips head (ref: MescaBug's & other's photos) screws and you'll have them. The current 'replacement' screws being offered, commercially, are not the same and fit poorly.

I think if you PM a member who has had this done to their receiver, they can be of some help in pointing you to a qualified and competent master machinist/gunsmith.

It's not necessary, but it's like... way KOOL.

Talked to a guy, who talked to a guy... ? Really? - That's it? We (collectively) NEED that formula. Your task is to procure it (from that last guy,) by any means necessary and share it on this forum. Try alcohol, but personally, I'm indifferent to your method.

Good Luck!!

Question(s):

2. I have a sight base that has the look, but isn't period correct. Where do ya'll find the best sources for these?

Current purchase source link (good for ~6 Days)

Remington Model 700 s A Redfield Scope Mount Base w Rings | eBay

5. Buttplate Screws: One member said he thinks they're off a 740, can any substantiate that? They do look correct to me and I think the guy is right, just looking for further affirmation.

Butt plate screws from the Early 742's will also fit. Look for the early/original Remington 'deep-well' Phillips head (ref: MescaBug's & other's photos) screws and you'll have them. The current 'replacement' screws being offered, commercially, are not the same and fit poorly.

6. Clipslotting:

Who can do this?

I think if you PM a member who has had this done to their receiver, they can be of some help in pointing you to a qualified and competent master machinist/gunsmith.

Is it necessary?

It's not necessary, but it's like... way KOOL.

7. Parkerizing: Who can do this? I've seen some people think the green tint of because of the oil they put on these rifles. Would parking the barelled action and dunking it in cosmoline and bombarding it with UV light work? I'm thinking along the lines of how Garands got their green color (maybe.) It might be a long shot, but I talked to a guy who swore by it.

Talked to a guy, who talked to a guy... ? Really? - That's it? We (collectively) NEED that formula. Your task is to procure it (from that last guy,) by any means necessary and share it on this forum. Try alcohol, but personally, I'm indifferent to your method.

Good Luck!!

Last edited:

D

Deleted member 10043

Guest

Rings and bases

Left rings and bases I acquired in 2006 and are still available through Redfield/Leupold. The base is no different then the previous 511227 base Redfield produced.

Middle rings and base are the Redfield 522000 rings and 511227 base. I discovered that the factory bluing is pretty basic and comes off with kitchen or bath chemicals. As a result of fucking up the bluing, these have a semi-cold bluing using Vann's Bluing and then Hoppe's gun oil and the oven @350 until about 10 minutes after the oil started smoking. Sort of like curing a cast iron skillet. This definitely left a patina.

Right rings and base are the "722" square corner base that is long enough in the rear to expose the clip slot though the clip slot cannot be accessed when mounted so I don't think this base or the 40x base is necessary for a rig that is not clip slotted unless you are that anal . The rings are 522000 with the original gloss bluing.

. The rings are 522000 with the original gloss bluing.

One thing I noticed about the older Redfield stuff is that the front dove tail can be slightly loose from previous installs. Don't know if this is because of the ring dove tail or the base itself. Personally, I would use a little Permatex to hold that front dovetail once installed with a scope.

Merry Christmas!

Left rings and bases I acquired in 2006 and are still available through Redfield/Leupold. The base is no different then the previous 511227 base Redfield produced.

Middle rings and base are the Redfield 522000 rings and 511227 base. I discovered that the factory bluing is pretty basic and comes off with kitchen or bath chemicals. As a result of fucking up the bluing, these have a semi-cold bluing using Vann's Bluing and then Hoppe's gun oil and the oven @350 until about 10 minutes after the oil started smoking. Sort of like curing a cast iron skillet. This definitely left a patina.

Right rings and base are the "722" square corner base that is long enough in the rear to expose the clip slot though the clip slot cannot be accessed when mounted so I don't think this base or the 40x base is necessary for a rig that is not clip slotted unless you are that anal

One thing I noticed about the older Redfield stuff is that the front dove tail can be slightly loose from previous installs. Don't know if this is because of the ring dove tail or the base itself. Personally, I would use a little Permatex to hold that front dovetail once installed with a scope.

Merry Christmas!

Attachments

Got the scope in today and ordered the buttplate screws from Numrich. I've also had a shit ton of fun shooting the Red Ryder BB gun I got myself for Christmas. I haven't figured out how to mount the accurange to the BB gun yet.

On another note, my grandfather died in June and I was looking through his stuff. Found a Weaver K4 El Paso in a Tasco box. That was exciting. Being that his deer rifle had a K4 on it. Damn I miss him, but the knowledge of hunting and fishing he taught me I've been passing on as often as I can.

Rifle is a Savage Model 45 Super Sporter in .30-06. Best rifle I've ever shot.

Me and Papa after I killed a deer. My favorite picture of him and me.

On another note, my grandfather died in June and I was looking through his stuff. Found a Weaver K4 El Paso in a Tasco box. That was exciting. Being that his deer rifle had a K4 on it. Damn I miss him, but the knowledge of hunting and fishing he taught me I've been passing on as often as I can.

Rifle is a Savage Model 45 Super Sporter in .30-06. Best rifle I've ever shot.

Me and Papa after I killed a deer. My favorite picture of him and me.

JStill waiting on my stock.... Silver Hill has told me "We're making 12 right now, its shpping Friday" for the last 3 weeks. Not sure what's going on there.... I told him only ordered 1, not 12...

Ha, I was told the same thing when I ordered one 2 weeks ago. How long did it take you to get your stock?

Ha, I was told the same thing when I ordered one 2 weeks ago. How long did it take you to get your stock?

Please... Don't get me started. I did get a stock. Hours and hours of sanding, pillar bedded it, and it's a bit off for being sold as a "95% inletted stock". I would say I got a 75% inletted stock. But, the forend drifts to the left. Can't take anymore off without it being noticeable, so I have a tiny point of contact on the first inch of the stock against the barrel. Confirme with a piece of thin cardboard. Found this out as I've been relieving it so much. The cutout for the floor plate and trigger guard is also off. I had to shift it over and fill it in. Rob said he would replace it. So I'm still waiting on a new stock. Told him to check (and recheck) geometry before sending it out.

Here is the finished color. Used Real Milk Paint Dark Raw Tung Oil, then BLO , finished up with my homemade 1/3 mix (melted beeswax, turpentine and BLO to a shoe polish consistency) All for naught......

Last edited:

Few folks asked about the stock finish. As follows:

1A. A lot of coats of Real Milk Paint Company Dark Raw Tung Oil (DRTO) First 3 applied with 0000 steel wool. After sanding the stock (I used 200 and 220 grit), soak up the steel wool with the dark oil and apply it heavily. Let it sit 10 minutes, wipe off (don't want any stray strands of steel wool to dry in the finish). Then wipe on a thin coat with a foam brush.

Let dry 12 hours. wipe down with a clean cloth the next day.

The DRTO is basically raw tung oil with a ton of dark chocolate colored carbon added. It builds up on the bottom if you let it sit for a while. It's all natural stuff, and you usually use this stuff for eating surfaces. You can apply it with your bare hands BUT it stains. Wear gloves.

REPEAT This 4 or 5 (do 3 coats with the steel wool, last one or two with the foam brush or rag). Rub it lightly with the steel wool. With the grain. Not to hard. You're just really trying to work the surface, build some heat with the friction. Don't really press down hard otherwise you'll just scrape off the previous coats.

You will see the stock darken with each successive coat.

1B. **Now, if you don't want to buy DRTO, then you can try a coat of Feibings Chocolate Brown Leather Dye. Yes, leather dye. It's better than stain. Put pre-finish (Wood Sealer) on the wood

then apply the leather dye. Since it's alcohol based, it dries fast. !!!!! WEAR VINYL GLOVES!! This crap stains your hands and does not come off unless you use Acetone or Denatured alcohol. I was out of both and had to use my damn Vodka once. It was that bad.!!! Once it dries (5 minutes) wipe if down with a rag. REALLY wipe it down. Let it dry overnight and repeat until you get a color SLIGHTLY darker than you want.

Now, you can use STAIN. Yes, stain. The stain will bring out the undertones and some of the graining. WAIT until the leather dye dries a few days. Let it dry out...

2. I then move on to BLO to get a bit more a sheen. Wipe/foam brush on a nice coat (**rinse your rag or brush with water. This shit goes on fire if you roll it up in ball and let it dry!!**) Let it sit for 1/2 hour. Wipe off excess and let the stock dry overnight.

REPEAT 4 or 5 times, or until you're happy with the sheen.

2B. If you didn't do the Tung Oil, put the 1st 3 coats of BLO on with the steel wool method. This is why I said make it a bit darker, the steel wool with lighten up the wood a bit by removing some of the leather dye. Then do your 3 - 4 finish coats of BLO.

Let it dry for a few days.

3. Apply Tom's 1/3 mix (you can make it yourself). Or you can skip this all together. I like the finish it adds.

This puts on a Beeswax based coating, so be aware that if you're going to refinish or stain the stock a few years down the road, you have to get ALL this beeswax off.

1A. A lot of coats of Real Milk Paint Company Dark Raw Tung Oil (DRTO) First 3 applied with 0000 steel wool. After sanding the stock (I used 200 and 220 grit), soak up the steel wool with the dark oil and apply it heavily. Let it sit 10 minutes, wipe off (don't want any stray strands of steel wool to dry in the finish). Then wipe on a thin coat with a foam brush.

Let dry 12 hours. wipe down with a clean cloth the next day.

The DRTO is basically raw tung oil with a ton of dark chocolate colored carbon added. It builds up on the bottom if you let it sit for a while. It's all natural stuff, and you usually use this stuff for eating surfaces. You can apply it with your bare hands BUT it stains. Wear gloves.

REPEAT This 4 or 5 (do 3 coats with the steel wool, last one or two with the foam brush or rag). Rub it lightly with the steel wool. With the grain. Not to hard. You're just really trying to work the surface, build some heat with the friction. Don't really press down hard otherwise you'll just scrape off the previous coats.

You will see the stock darken with each successive coat.

1B. **Now, if you don't want to buy DRTO, then you can try a coat of Feibings Chocolate Brown Leather Dye. Yes, leather dye. It's better than stain. Put pre-finish (Wood Sealer) on the wood

then apply the leather dye. Since it's alcohol based, it dries fast. !!!!! WEAR VINYL GLOVES!! This crap stains your hands and does not come off unless you use Acetone or Denatured alcohol. I was out of both and had to use my damn Vodka once. It was that bad.!!! Once it dries (5 minutes) wipe if down with a rag. REALLY wipe it down. Let it dry overnight and repeat until you get a color SLIGHTLY darker than you want.

Now, you can use STAIN. Yes, stain. The stain will bring out the undertones and some of the graining. WAIT until the leather dye dries a few days. Let it dry out...

2. I then move on to BLO to get a bit more a sheen. Wipe/foam brush on a nice coat (**rinse your rag or brush with water. This shit goes on fire if you roll it up in ball and let it dry!!**) Let it sit for 1/2 hour. Wipe off excess and let the stock dry overnight.

REPEAT 4 or 5 times, or until you're happy with the sheen.

2B. If you didn't do the Tung Oil, put the 1st 3 coats of BLO on with the steel wool method. This is why I said make it a bit darker, the steel wool with lighten up the wood a bit by removing some of the leather dye. Then do your 3 - 4 finish coats of BLO.

Let it dry for a few days.

3. Apply Tom's 1/3 mix (you can make it yourself). Or you can skip this all together. I like the finish it adds.

This puts on a Beeswax based coating, so be aware that if you're going to refinish or stain the stock a few years down the road, you have to get ALL this beeswax off.

Last edited:

... Hours and hours of sanding, pillar bedded it, and it's a bit off for being sold as a "95% inletted stock". I would say I got a 75% inletted stock. But, the forend drifts to the left. Can't take anymore off without it being noticeable, so I have a tiny point of contact on the first inch of the stock against the barrel. Confirmed with a piece of thin cardboard. Found this out as I've been relieving it so much. The cutout for the floor plate and trigger guard is also off. I had to shift it over and fill it in.

Just curious... with all of this drifting and contacting and fitting and refitting and relieving and shifting, going on, to fit your barreled action, trigger group and bottom metal... to this stock... were you using 'inletting black' as an aide??

Just curious... with all of this drifting and contacting and fitting and refitting and relieving and shifting, going on, to fit your barreled action, trigger group and bottom metal... to this stock... were you using 'inletting black' as an aide??

I use crushed carbon; Expo markers; colored chalk... really anything I have that will "rub off" and show occlusions/contact. I didn't do any "refitting". Just fitting.

So here is the start of my attempt to make an accurate build

I have 90% stock and the brass insert, an old 60s 40X action with the short bolt shroud, double sear tombstone trigger, a NOS Redfield scope mount, a set of NOS Redfield 1" rings with the 4 slotted screws, the correct end plate, the only thing is that the barrel is a 22" Hart but it shoots a ragged hole so I might keep it a while till I decide to rebarrel. Still looking for that magic gen 1 scope to have re-anodized in order to make this a perfect period correct gen 1 M40 model. I went with the 40X since some have speculated that some of the first were 40Xs. The only other things beside the barrel that I need to correct, if I feel like doing so, is the internal magazine came with the cut aways and the bottom metal. I had it personalized and sitting around for a build for myself one day. So this is going to be the build I use it on. Any insight or corrections from you guys would be appreciated

Thanks

I have 90% stock and the brass insert, an old 60s 40X action with the short bolt shroud, double sear tombstone trigger, a NOS Redfield scope mount, a set of NOS Redfield 1" rings with the 4 slotted screws, the correct end plate, the only thing is that the barrel is a 22" Hart but it shoots a ragged hole so I might keep it a while till I decide to rebarrel. Still looking for that magic gen 1 scope to have re-anodized in order to make this a perfect period correct gen 1 M40 model. I went with the 40X since some have speculated that some of the first were 40Xs. The only other things beside the barrel that I need to correct, if I feel like doing so, is the internal magazine came with the cut aways and the bottom metal. I had it personalized and sitting around for a build for myself one day. So this is going to be the build I use it on. Any insight or corrections from you guys would be appreciated

Thanks

So here is the start of my attempt to make an accurate build

I have 90% stock and the brass insert, an old 60s 40X action with the short bolt shroud, double sear tombstone trigger, a NOS Redfield scope mount, a set of NOS Redfield 1" rings with the 4 slotted screws, the correct end plate, the only thing is that the barrel is a 22" Hart but it shoots a ragged hole so I might keep it a while till I decide to rebarrel. Still looking for that magic gen 1 scope to have re-anodized in order to make this a perfect period correct gen 1 M40 model. I went with the 40X since some have speculated that some of the first were 40Xs. The only other things beside the barrel that I need to correct, if I feel like doing so, is the internal magazine came with the cut aways and the bottom metal. I had it personalized and sitting around for a build for myself one day. So this is going to be the build I use it on. Any insight or corrections from you guys would be appreciated

Thanks

Is the floorplate/guard aluminum or steel?

Getting close. I got the stock yesterday from Silver Hill. I have probably 6 hours in it so far. The base I got from eBay for like $15 and the scope was another eBay find. It doesn't have the range finder reticle but I don't care. The rifle is a 2006ish PSS which has a 26" barrel but who cares.

Last edited:

Not sure that i want to sell the mount. Would much rather trade it for something else just as cool. Im sure as soon as i part with it, i will need it. That always happens.

D

Deleted member 10043

Guest

This should help in finding a correct Redfield scope for the period the M40 was introduced. I got this from a '66 catalog

Reticle type followed by item number.

3-9x Variable

4P CCH 112013

Fine Crosshair 112000

Med. Crosshair 112001

Heavy Crosshair 112002

Post w./crosshair 112003

3 to 1 Dot 112004

3-9x Variable Accu-Range

4P CCH 112014

Fine Crosshair 112006

Med. Crosshair 112007

Heavy Crosshair 112008

Post w./crosshair 112009

3 to 1 Dot 112010

4P CCH is a duplex reticle. 3 to 1 dot is a is a crosshair reticle with a dot at the intersection.

Reticle type followed by item number.

3-9x Variable

4P CCH 112013

Fine Crosshair 112000

Med. Crosshair 112001

Heavy Crosshair 112002

Post w./crosshair 112003

3 to 1 Dot 112004

3-9x Variable Accu-Range

4P CCH 112014

Fine Crosshair 112006

Med. Crosshair 112007

Heavy Crosshair 112008

Post w./crosshair 112009

3 to 1 Dot 112010

4P CCH is a duplex reticle. 3 to 1 dot is a is a crosshair reticle with a dot at the intersection.

I'm at the "BUY NOW" button...

My finger's a twitch'n... There's no box, so how do I know what I'm gett'n.

I'm a scrounger, by training, which means, by and large, that the boxes are long-long gone and I'm looking for physical characteristics and markings. The Gen.I and Gen.II scopes are serial numbered, but where do these numbers, i.e., 112006, 112007, etc., appear, outside of a period catalog?

How do they help us, for example, determine if an Accurange has a medium and not a fine crosshair? For myself (as well as other lurkers- yeah, you're out there,) I'm always looking for any bit of information that can make my searches more productive and my money well spent.

As always, thanks, in advance.

This should help in finding a correct Redfield scope for the period the M40 was introduced. I got this from a '66 catalog

Reticle type followed by item number.

3-9x Variable

4P CCH 112013

Fine Crosshair 112000

Med. Crosshair 112001

Heavy Crosshair 112002

Post w./crosshair 112003

3 to 1 Dot 112004

3-9x Variable Accu-Range

4P CCH 112014

Fine Crosshair 112006

Med. Crosshair 112007

Heavy Crosshair 112008

Post w./crosshair 112009

3 to 1 Dot 112010

4P CCH is a duplex reticle. 3 to 1 dot is a is a crosshair reticle with a dot at the intersection.

My finger's a twitch'n... There's no box, so how do I know what I'm gett'n.

I'm a scrounger, by training, which means, by and large, that the boxes are long-long gone and I'm looking for physical characteristics and markings. The Gen.I and Gen.II scopes are serial numbered, but where do these numbers, i.e., 112006, 112007, etc., appear, outside of a period catalog?

How do they help us, for example, determine if an Accurange has a medium and not a fine crosshair? For myself (as well as other lurkers- yeah, you're out there,) I'm always looking for any bit of information that can make my searches more productive and my money well spent.

As always, thanks, in advance.

Jake:

Looking good. I have the same scope. I don't care about the reticle as well. The Marines didn't use the tombstone for shit.

They kept it on 9x and estimated hold over... Half the tombstones fell off anyway.

Some 95% stock, huh? Mine was a mess, they actually sent me another one. But I pillar bedded the other, it's friggin' tight. And it came out nice. I'm gonna hold on to the other one and fit it when I'm ready... Or build another rifle. Lol. Lord know I got plenty of scopes!!Getting close. I got the stock yesterday from Silver Hill. I have probably 6 hours in it so far. The base I got from eBay for like $15 and the scope was another eBay find. It doesn't have the range finder reticle but I don't care. The rifle is a 2006ish PSS which has a 26" barrel but who cares.

I had the same floor plate. Stripped off the paint and and sanded it smooth, anodized it black. Looks like the originals. It's painted, btw. Get the 513t swivels from Sarco for $10 a piece. You can get slot head receiver screws from Brownells. You're also a bit "proud" by the ejection port, or whatever it's called. This was my issue.

Similar threads

- Replies

- 13

- Views

- 1K