Yes you’re correct, ejector plunger. I’ve seen Cortina’s video. Like I said, you can’t easily remove the plunger from a Scar17 without having to replace the clip and I hear it’s a real PITA to re-install. So that is out of the question. And I guess if I zeroed caliper, it’d probably work fine for the .002”You may be referring to the ejector(plunger) rather than the extractor(hook), because the spring tension on the plunger can theoretically push the case further into the chamber, giving a false reading on the headspace dimension from breech face to the datum line on the shoiulder of the chamber. With the ejector plunger and spring removed you can simply chamber a dummy/empty case and see how easy it is to lock up the bolt lugs, when it gets tight you have reached the maximum headspace dimension for your cartridge case that will still fit in your rifles chamber. Erik Cortina has demonstrated this on his custom F class rig, where the bolt handle either closes fully just on gravity or it hangs up and needs force to get it closed.[If I'm not mistaken his rifles do not have any ejector plungers in the bolts, you can easily notice him not only hand loading but hand ejecting in his videos)

The plunger will also affect the base to ogive/lands measurement and comes into play when you insert a modified case with the Hornady gauge. That is a different gauge than posters have shown here, rather"Comparator" in this context of sizing brass, generally refers to the gadget that you put on one of the forks of dial or digital calipers, they do not give an abs absolute measurement and are useless for comparing to SAAMI spec diagrams, as has already been pointed out here, those measuring tools only allow you to compare two cases. You do not zero it against the fork, but rather against another case. For instance you put in a fire formed case, then zero on that baseline and it will tell you how many thousandths you are bumping back the shoulder on a resized case.

Used properly those comparators will be yielding numbers like"-0.002" never "1.638"

Whidden dies, incidentally, come with a comparator that fits the caliper fork without the red adaptor. I am also a fan of the RCBS precision case micrometer.

And if nobody's said it yet if you plan on hunting with that rifle in cold weather it's always a good idea to completely disassemble and the grease the bolt assembly and use dry lube when reassembling. You don't want grease to harden from the combination of temperature changes and condensation.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

308 Winchester AR Only

- Thread starter padom

- Start date

I just picked up a box of these to try. Look good on paper. BC is better than a 175 TMK.

Anyone ever shot these, have any data?

If not I'm your Huckleberry. If they shoot well in my AR I think this will be my go to 308 Deer bullet.

BTW I didn't wipe em out, left 2 boxes for you fellas @ Blue Collar.

Anyone ever shot these, have any data?

If not I'm your Huckleberry. If they shoot well in my AR I think this will be my go to 308 Deer bullet.

BTW I didn't wipe em out, left 2 boxes for you fellas @ Blue Collar.

Those Speer Impacts should work well for Der hunting, they look similar to the Nosler Accubonds and the Hornady Interbonds @ around the same price point.

Working up a load for 165 game changers in a 18” barrel using Varget and LC brass seated to mag length. I used magnum primers, as I have a shitload of em. At 41.6 grains, I’m getting 2560 fps. At 42.2, 2605 fps. No pressure signs. Does this seem fast for an 18” barrel?

I’m not loading for speed, so trying to stay within reasonable pressure.

I’m not loading for speed, so trying to stay within reasonable pressure.

Last edited:

Working up a load for 165 game changers in a 18” barrel using Varget and LC brass seated to mag length. I used magnum primers, as I have a shitload of em. At 41.6 grains, I’m getting 2560 fps. At 42.2, 2605 fps. No pressure signs. Does this seem fast for an 18” barrel?

I’m not loading for speed, so trying to stay within reasonable pressure.

For a 165 gr bullet out of an 18" barrel... That 2605 strikes me as pretty fast. But if you aren't getting pressure signs... I would roll with it... Albeit carefully.

Mike

Agree with Okiemike.Working up a load for 165 game changers in a 18” barrel using Varget and LC brass seated to mag length. I used magnum primers, as I have a shitload of em. At 41.6 grains, I’m getting 2560 fps. At 42.2, 2605 fps. No pressure signs. Does this seem fast for an 18” barrel?

I’m not loading for speed, so trying to stay within reasonable pressure.

Depends on bearing surface of that game changer & if you have a fast or slow barrel.

I like to use factory ammo as a reference point for my barrels. FGMM 168’s run 2622 avg. from my 18” Proof on a Magneto V3. This is a pretty fast barrel.

Bearing surface has a big affect on pressure. Not sure how bearing surface of a 165 compares the 168smk? If your barrel is average speed wise and the 165’s have more bearing surface than a smk, then you might be on the warm side with that 2605 load.

Have you ever loaded any smk with varget for a comparison to the Game Changers?

I haven’t loaded anything else. Just 175 DTAC loaded ammo @ 2520 and Winchester M80 ball runs 2716. 1:10” Aero barrel, omega 300, magneto V3, adj gas block, JP SCS. I’ll see if there is a box of 168 Fgmm in town. Good call on that.Agree with Okiemike.

Depends on bearing surface of that game changer & if you have a fast or slow barrel.

I like to use factory ammo as a reference point for my barrels. FGMM 168’s run 2622 avg. from my 18” Proof on a Magneto V3. This is a pretty fast barrel.

Bearing surface has a big affect on pressure. Not sure how bearing surface of a 165 compares the 168smk? If your barrel is average speed wise and the 165’s have more bearing surface than a smk, then you might be on the warm side with that 2605 load.

Have you ever loaded any smk with varget for a comparison to the Game Changers?

I load 165 grain SGKs out of my 16” ARs. I use 42.8 grains of Varget in LC prepped cases. I get in the high 2404 out of my rifles. I just used the same load I have for my SMKs. I’m trying to work up again for the tipped game kings with 4064 since Varget is unobtanium in my neck of the woods.Working up a load for 165 game changers in a 18” barrel using Varget and LC brass seated to mag length. I used magnum primers, as I have a shitload of em. At 41.6 grains, I’m getting 2560 fps. At 42.2, 2605 fps. No pressure signs. Does this seem fast for an 18” barrel?

I’m not loading for speed, so trying to stay within reasonable pressure.

To close this out for anyone tracking, Out of my 18” barrel:I haven’t loaded anything else. Just 175 DTAC loaded ammo @ 2520 and Winchester M80 ball runs 2716. 1:10” Aero barrel, omega 300, magneto V3, adj gas block, JP SCS. I’ll see if there is a box of 168 Fgmm in town. Good call on that.

175 FGMM @ 2450

168 FGMM @ 2585

Thanks for the help. That 168 FGMM has questioning whether I even should try and reload.

Attachments

.....well, if you do decide to reload, you already have some of the data parameters answered by replicating the components used in the FGGM, i.e., bullets, brass, primers and the CBTO, COAL, shoulder bump, trim length (easily determined by de-constructing a single FGGM round). The powder used in the FGGM is the variable, but experimentation has been done by countless reloaders and published in countless articles/forums/etc.To close this out for anyone tracking, Out of my 18” barrel:

175 FGMM @ 2450

168 FGMM @ 2585

Thanks for the help. That 168 FGMM has questioning whether I even should try and reload.

Looking for info on reloads for my AR10. I have an 18” barrel 1/10 twist. My reloads have been 168 sierra BTHP, armscor precision brass, and tac powder. I’ve had no luck with any decent groupings at 100 yards with loads from 41 through 42.9 (increments of .2 through that range of weights). Just looking for some more insight. All brass is full length resized, trimmed to 2.010 chamfered/ de-burred, with an OAL of 2.80. Thanks for the help.

I use the federal 168 gold metal for my initial warm up. I have actually got the best grouping so far from this ammo, though not anywhere close to where I’d like to be. I do plan on checking the scope, and I’m curious if there is anything else besides that I should be checking gun wise?The usual advice is to doublecheck scope mount then try a box of federal gold medal just to verify the rifle is OK.

It may or may not be of help but, cfe223 in a 20 inch bolt gun with the same mag lenght / chamber restrictions as an ar never got past 1 moa much.

Instantly varget did with no other

changes to components. I just got hold of tack to try.

Good luck.

Instantly varget did with no other

changes to components. I just got hold of tack to try.

Good luck.

3031 ? With the usual powders for reloading the 308 ,either bolt or AR being non existent, has anyone tried or used 3031, but gave up,more because it didn't meter worth a crap ?

Hodgdon's site shows some interesting data

Hodgdon's site shows some interesting data

The fgmm 168 smk is a very good standard to use.Looking for info on reloads for my AR10. I have an 18” barrel 1/10 twist. My reloads have been 168 sierra BTHP, armscor precision brass, and tac powder. I’ve had no luck with any decent groupings at 100 yards with loads from 41 through 42.9 (increments of .2 through that range of weights). Just looking for some more insight. All brass is full length resized, trimmed to 2.010 chamfered/ de-burred, with an OAL of 2.80. Thanks for the help.

A little more info on testing and firearm would help the people here.

100 yd,

Bench? sand bags? Shooting in the artic tundra or swetting like dog in the Texas heat? Muzzle device?

Performance of factory ammo (moa) and your best round.

As far as your loading regime I add running a separate neck mandrell die. I undersize my necks then separately expand them.

It shrank groups in everything.

Same problem with 4895.3031 ? With the usual powders for reloading the 308 ,either bolt or AR being non existent, has anyone tried or used 3031, but gave up,more because it didn't meter worth a crap ?

Hodgdon's site shows some interesting data

NO, I've found some 3031, but there isn't any IMR 4064, or either 4895's to be foundSame problem with 4895.

There's a third 4895 from Accurate called 2495. It's made in the same facility ( General Dynamics Valleyfield, Ontario Canada) as the IMR 4895 version. The Accurate 4064 is made there also. They both are going to be very similar to their IMR counterparts. They were both sourced overseas years ago, but are now made in North America.

Both worth a try. I have 2#'s left of the Czech Republic Accurate 4064. When it's used up, I'll purchase some of the new Accurate 4064. The Czech stuff is very good.

Both worth a try. I have 2#'s left of the Czech Republic Accurate 4064. When it's used up, I'll purchase some of the new Accurate 4064. The Czech stuff is very good.

When I want to compare one powder against another one I go to the Hodgdon data site. They did add data from the Western site. And as long as they use the same testing method , actual pressure test barrels or some computer program, it's apples to apples and not apples to avocados. Is your AA 4064 as bulky as I 4064 ? To me, that's the + for I 4064 as you get 100% loading density .There's a third 4895 from Accurate called 2495. It's made in the same facility ( General Dynamics Valleyfield, Ontario Canada) as the IMR 4895 version. The Accurate 4064 is made there also. They both are going to be very similar to their IMR counterparts. They were both sourced overseas years ago, but are now made in North America.

Both worth a try. I have 2#'s left of the Czech Republic Accurate 4064. When it's used up, I'll purchase some of the new Accurate 4064. The Czech stuff is very good.

Hodgdon data site

AA 4064 is short grained, similar to H-4895.Is your AA 4064 as bulky as I 4064 ? To me, that's the + for I 4064 as you get 100% loading density .

Hodgdon data site

The AA 4064 loads better in the 223 Rem. because it's shorter grained than the IMR version.

AA 4064 worked well for me in 223 With heavier bullets It also worked well in the 308 Win.

The AA powders (2495, 4064 & 4350) give you another option if you can't find the IMR versions and they are all made in North America now. That was the point of my post.

I was under the impression Aa4064 IS NOT equivalent to 4064. I recently bought10lbs and cancelled the order immediately after researching. AA4064 isnt really a 308 powder.AA 4064 is short grained, similar to H-4895.

The AA 4064 loads better in the 223 Rem. because it's shorter grained than the IMR version.

AA 4064 worked well for me in 223 With heavier bullets It also worked well in the 308 Win.

The AA powders (2495, 4064 & 4350) give you another option if you can't find the IMR versions and they are all made in North America now. That was the point of my post.

Anyone in the Texas/louisiana disctrict that have IMR4064 8lb kegs to trade for Fed210M primers? OR CCI 43 primers? even swap

Works fine in the 308Win. If you don't want to use it, don't. I found the burn speed about in line with Varget, RE-15 and IMR 4320. I'm down to 2#'s from 16#'s I bought years ago.AA4064 isnt really a 308 powder.

I've had some good loads for this G28 clone for a while, mostly using 175s with ARComp or Varget, but on a whim I decided to try some N150 because from recent experience the N100-series of powders really keep the barrel temp down when shooting long shot strings.

Knowing that this rifle likes the Lapua 175 Scenar-L at 2.785" COAL, I loaded up a range of 40.0-42.7gr of N150 and blasted away. The results were better than expected! Between 41.5 & 41.8 the POI returned to center with pretty tight groups and velocities around 2480fps (16.5" barrel). This is about 80fps slower than my other loads, but the heat production is noticeably less and the consistency between charge weights is a huge improvement.

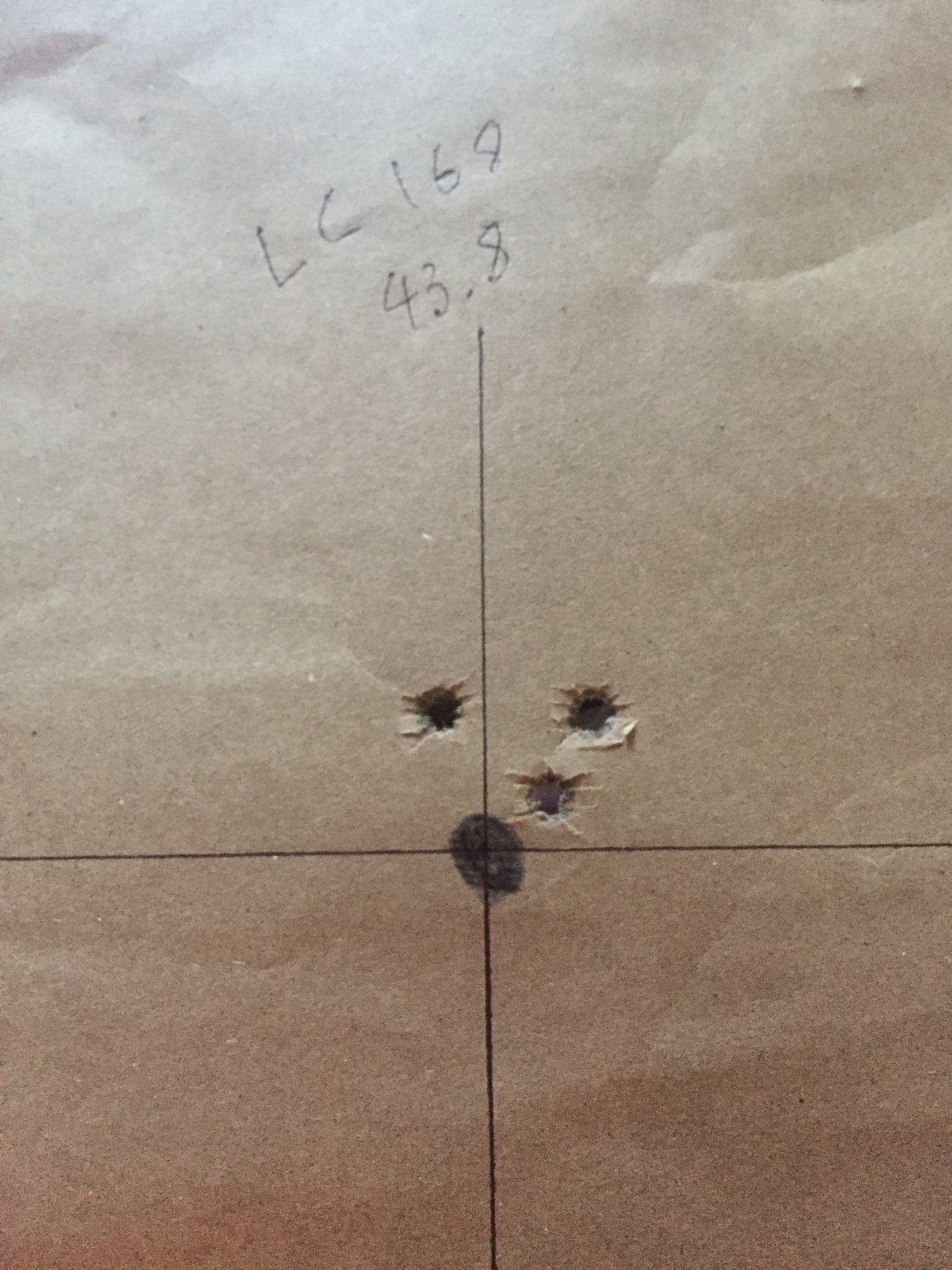

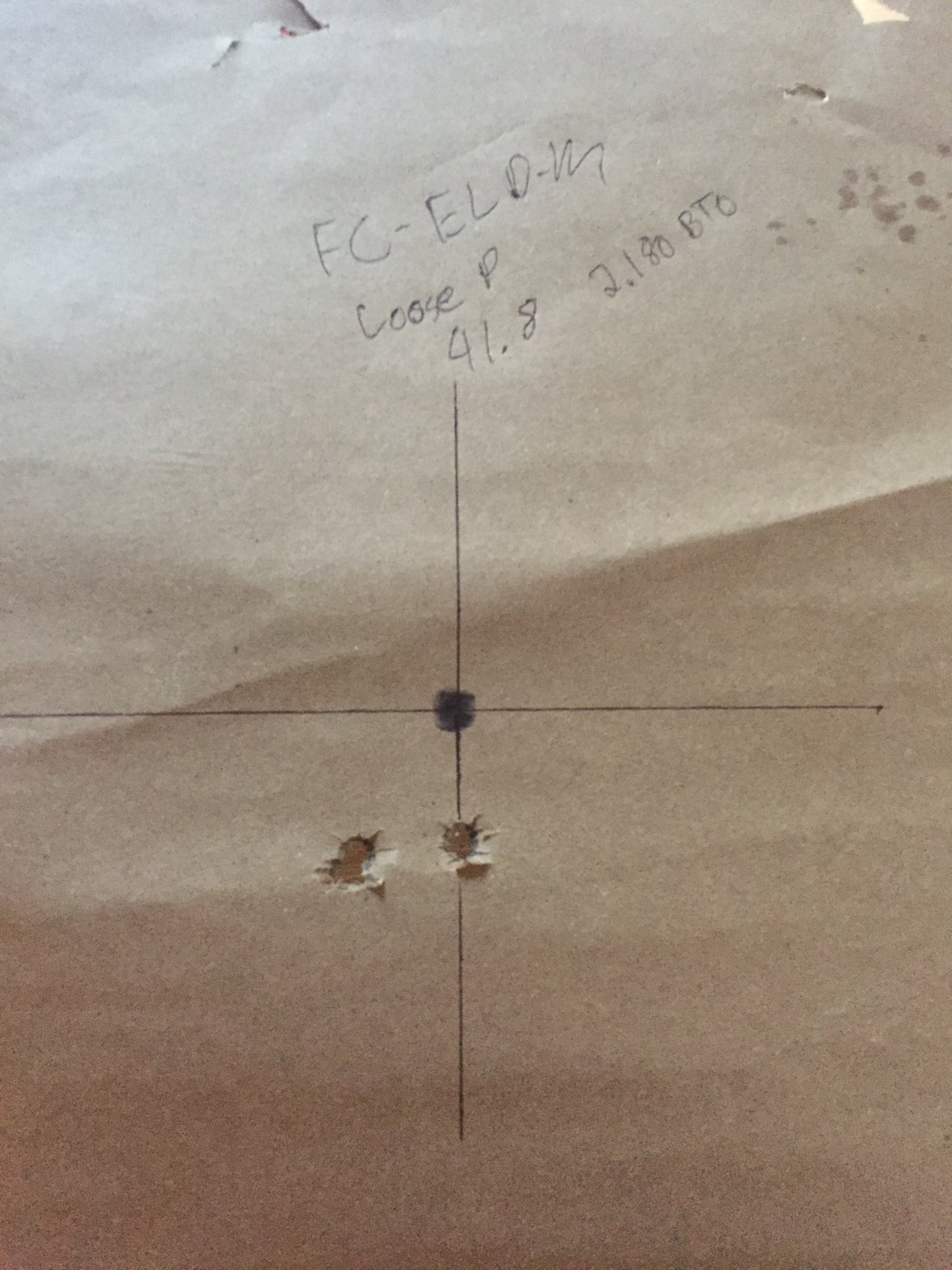

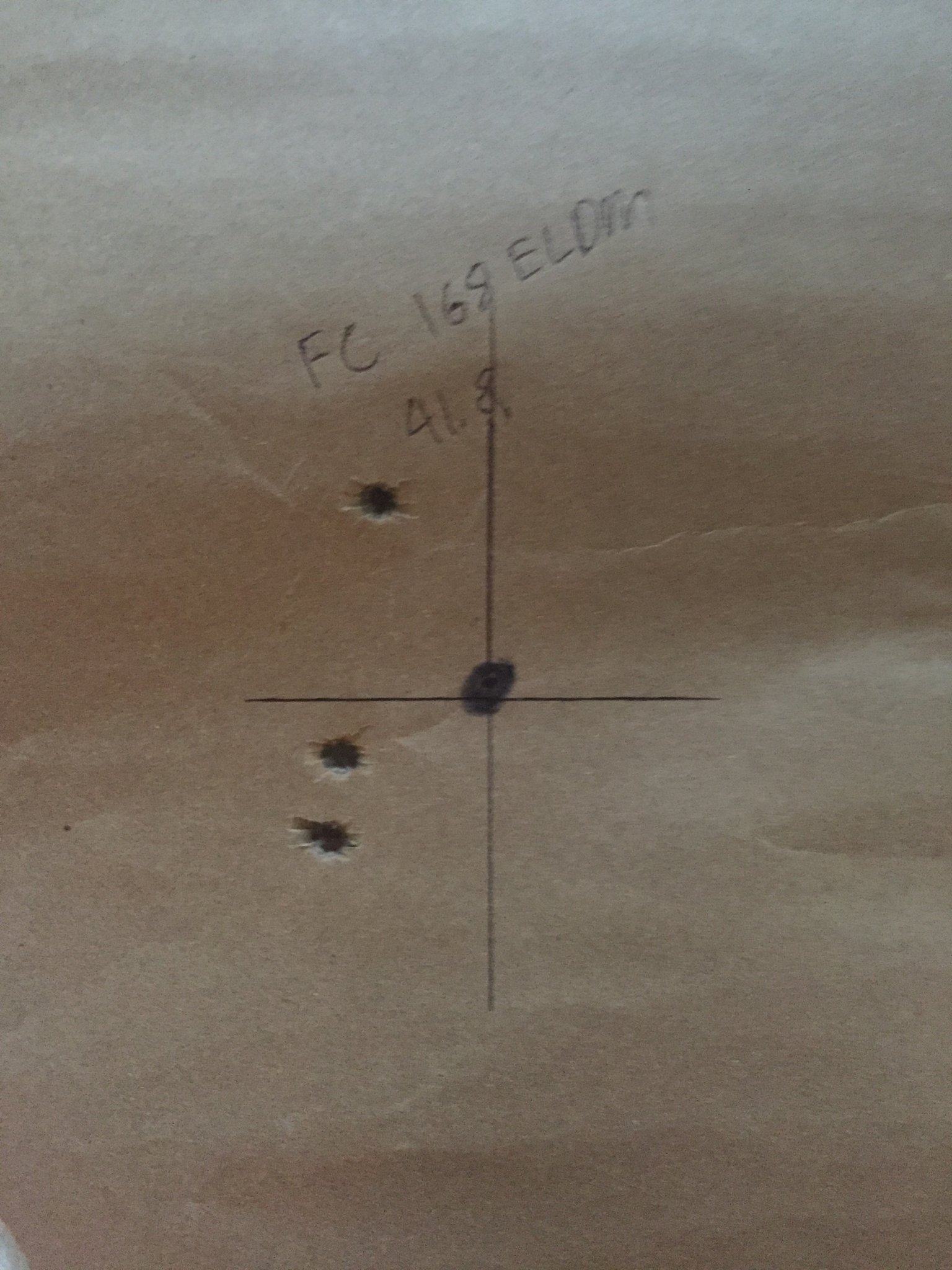

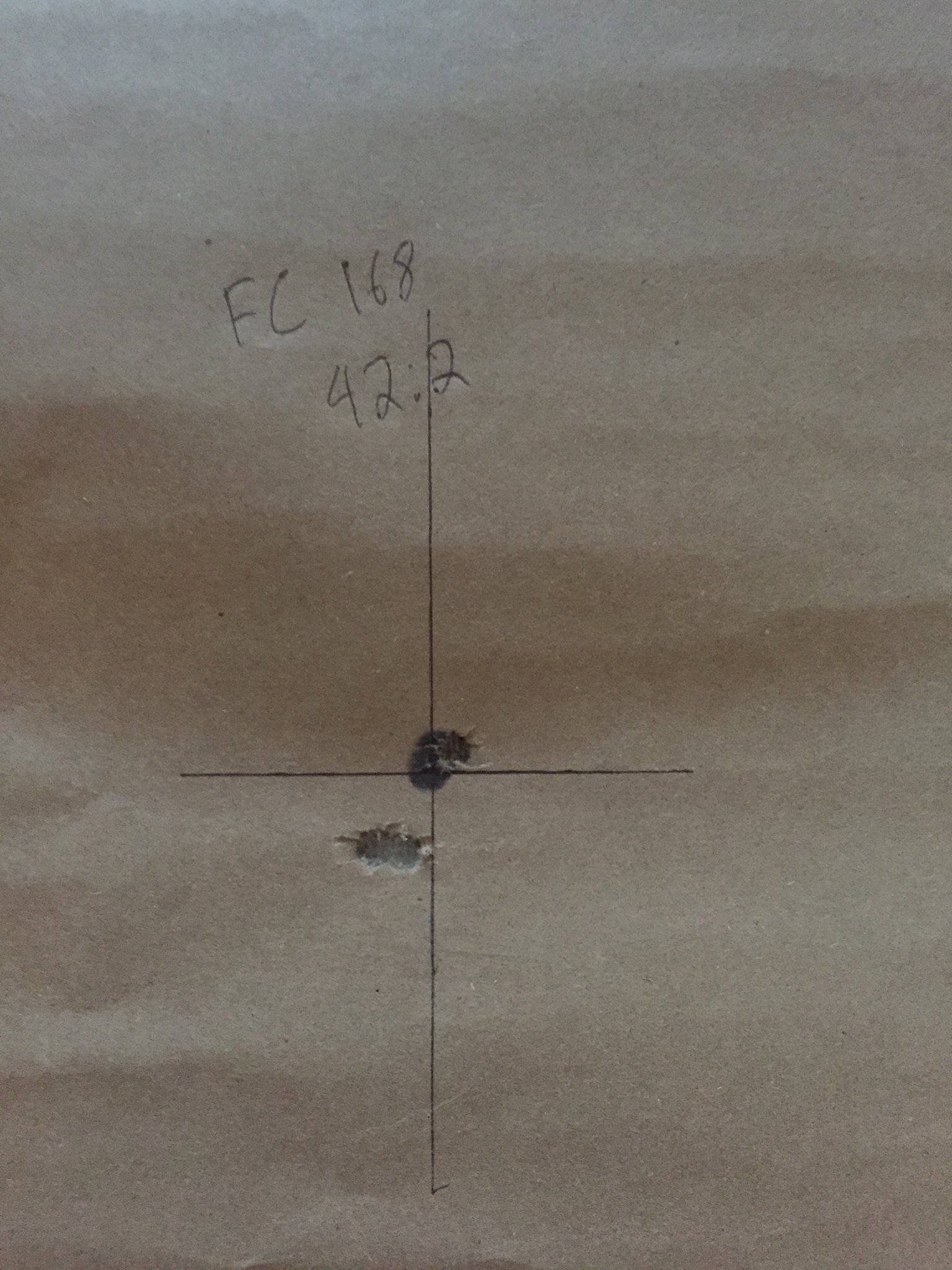

Had my Pof re barreled recently, re working some loads.

W748. 168 Smk, ball powder meters nice, .9”.

Imr 4064 Eldm

Flyers are me. Overlay the two 3 shot groups, 4 out of 6 around .8”. And tbe othe 2 and cringe...

4064 Eldm

Black dot gets lost in the reticle and I think I could do better with a different rear stock. Shot a .4” 3 shot last week but didn’t keep the target. Need to work on my consistency. New barrel shoots better than me!

W748. 168 Smk, ball powder meters nice, .9”.

Imr 4064 Eldm

Flyers are me. Overlay the two 3 shot groups, 4 out of 6 around .8”. And tbe othe 2 and cringe...

4064 Eldm

Black dot gets lost in the reticle and I think I could do better with a different rear stock. Shot a .4” 3 shot last week but didn’t keep the target. Need to work on my consistency. New barrel shoots better than me!

Looks like it's coming together.Had my Pof re barreled recently, re working some loads.

W748. 168 Smk, ball powder meters nice, .9”. View attachment 7923489

Imr 4064 EldmView attachment 7923490

View attachment 7923491

Flyers are me. Overlay the two 3 shot groups, 4 out of 6 around .8”. And tbe othe 2 and cringe...

4064 Eldm

View attachment 7923492

Black dot gets lost in the reticle and I think I could do better with a different rear stock. Shot a .4” 3 shot last week but didn’t keep the target. Need to work on my consistency. New barrel shoots better than me!View attachment 7923520

You mentioned using a different butt stock. I put a new one on mine and I think it's going to help... It has a flat bottom and should be much more stable on a rear bag... Before, I was playing a balancing act trying to stay on the bag.

I don't necessarily think it will turn my gun into a sub .5 moa gun. But I figure the more stable I am, the better.

The trade off is that it requires tools to set up and adjust this stock... Kind of a pain. But I'll deal with it if it helps shrink groups.

Had to go and refresh my memory to even see what it was. MagPul PRS Lite. I doubt it's top of the line, but it's what my local guy had on the shelf... And it's a step up from what I had.

Mike

Attachments

I know this thread is about load data, but I have some loads that I'm running with a COAL @ 2.875" and they just barely fit in the magazine. Is there anyone who makes a mag that will give me just a skosh more clearance for reliable feeding?

Mike

Mike

2.875 must be AICS with binder for bolt action?I know this thread is about load data, but I have some loads that I'm running with a COAL @ 2.875" and they just barely fit in the magazine. Is there anyone who makes a mag that will give me just a skosh more clearance for reliable feeding?

Mike

This is a AR thread, but ARC Mags for bolt get me over 2.9

Larue is about as good as it gets for Large Frame AR @ around 2.8”

Had my Pof re barreled recently, re working some loads.

Who did the barrel? ARs and rear bags, isn't that always a joy? I went today and fought mine. I swear to God, I'm just going to buy a good sling and be done with it, lol.

I know this thread is about load data, but I have some loads that I'm running with a COAL @ 2.875" and they just barely fit in the magazine. Is there anyone who makes a mag that will give me just a skosh more clearance for reliable feeding?

Mike

KAC and maybe Larue. Both are pricey.

No, it's for my AR... The factory mag that came with the rifle is the one that barely lets me get 2.875ish... They're 168 SMK's so there's enough variance in the meplats that some slip easily and others hang.2.875 must be AICS with binder for bolt action?

This is a AR thread, but ARC Mags for bolt get me over 2.9

Larue is about as good as it gets for Large Frame AR @ around 2.8”

It's not a do-or-die thing. I just chose that OAL because it put me .030 off the lands and still just barely clears the edge of the mag. When I find a powder charge that shows promise I'll probably end up seating them shorter until I find an OAL that groups well.

I figure I'll hit a good length somewhere between 2.800 and 2.875... just wanted to see if I had options just in case 2.875 turned out to be the magic spot.

I know, the whole scenario sounds weird.

Mike

They certainly are... The KAC seem to be unobtainium right now as it is. I believe I will definitely test seating depth before I dole out $$$ for the Larue.KAC and maybe Larue. Both are pricey.

Anyway... I've drug the thread off track enough. Back to load data.

Mike

POF did it, they actually covered it for free under warranty, which was pretty cool of them. They kinda do there own thing with those. BCG, bolt and barrel extension are Ar-15 sized and am unaware of anyone else who builds parts for them.Who did the barrel? ARs and rear bags, isn't that always a joy? I went today and fought mine. I swear to God, I'm just going to buy a good sling and be done with it, lol.

Wow 2.875 OAL with KAC and Larue mags? Would be interesting with secant and hybrid style bullets to push them out further. Most I can get out of the magpul st-25 is 2.830.

Just for a reference FGMM with 168g SMK's are loaded to a nominal 2.800 coal.

Base to ogive 2.110

They are sub moa in a lot of people's guns.

In my opinion 168's like to jump 0.04 to 0.06.

Stuff some varget under them and they will instantly fly.

Went and bought a batch of the 165g SGK shoved 42.4 varget under them and went under 1/2 moa but at 0.010 jump started having problems.

They moved the ogive forward on them by 0.060 so measure carefully . Not even going to buy smk 168's anymore.

A scope shelled and was replaced and the new shorter bto tests have not been shot yet.

Base to ogive 2.110

They are sub moa in a lot of people's guns.

In my opinion 168's like to jump 0.04 to 0.06.

Stuff some varget under them and they will instantly fly.

Went and bought a batch of the 165g SGK shoved 42.4 varget under them and went under 1/2 moa but at 0.010 jump started having problems.

They moved the ogive forward on them by 0.060 so measure carefully . Not even going to buy smk 168's anymore.

A scope shelled and was replaced and the new shorter bto tests have not been shot yet.

I'm running Peterson brass, but these are 168 SMK with IMR 4064 fired by BR2's... So my own version of FGMM.Just for a reference FGMM with 168g SMK's are loaded to a nominal 2.800 coal.

Base to ogive 2.110

They are sub moa in a lot of people's guns.

In my opinion 168's like to jump 0.04 to 0.06.

Stuff some varget under them and they will instantly fly.

Went and bought a batch of the 165g SGK shoved 42.4 varget under them and went under 1/2 moa but at 0.010 jump started having problems.

They moved the ogive forward on them by 0.060 so measure carefully . Not even going to buy smk 168's anymore.

A scope shelled and was replaced and the new shorter bto tests have not been shot yet.

18" tube, so I expect no records to be set. They'll be jogging, not sprinting. But groups are the goal.

Mike

Wow 2.875 OAL with KAC and Larue mags? Would be interesting with secant and hybrid style bullets to push them out further. Most I can get out of the magpul st-25 is 2.830.

I think the KAC is slightly longer than Larue. This morning they're both being difficult as I don't see the numbers listed on their websites. I "think" I measured one of my few KACs at 2.890, I'll check tonight. There is a review on Larue where a person says they measure 2.870.

Prior to our present situation, KACs were going for around $95 and the Larues were around $65, now they're both a lot more.

They certainly are... The KAC seem to be unobtainium right now as it is. I believe I will definitely test seating depth before I dole out $$$ for the Larue.

Anyway... I've drug the thread off track enough. Back to load data.

Mike

Real quick, measured the KAC and it seems like it will do 2.885 no problem, if you could find one. Just got in some Larues and they might do 2.875, definitely 2.870.

Thanks for the info!Real quick, measured the KAC and it seems like it will do 2.885 no problem, if you could find one. Just got in some Larues and they might do 2.875, definitely 2.870.

Mike

.308 is probably the most versatile cartridge when it comes to powder choices. Consult a burn rate chart, find a high and low, and pretty much everything in between is game...I am wanting to conserve my Varget cache for 6mm. I have not given up trying to find powder online, but I think it’ll be easier to pick up powder in my LGS. They have a good stock and selection, but it’s kinda random. So i am trying to collect a list of viable .308 powders, so i am not googling in the store. I have gone through this thread and the .308 Win. What other powders would you run in a .308?

Reloader15

IMR 4064

IMR 4166

IMR 4895

Ramshot Tac

BLC-2

VV N550

VV 150

Shooters World Precision

Shooters World Long Rifle

AR Comp

CFE223

8208XBR

H4895

H380

H322

H355

Benchmark

3031 ? With the usual powders for reloading the 308 ,either bolt or AR being non existent, has anyone tried or used 3031, but gave up,more because it didn't meter worth a crap ?

Hodgdon's site shows some interesting data

FWIW, The old school Marine loading was 39.5gr under a 168SMK

AR10 .308 20" Wilson Combat heavy barrel

168gr ELD-Match

44gr BLC(2)

CCI Br

Alpha brass

avg. 1700 fps (10rnds)

.74 MOA 100yrds

168gr ELD-Match

44gr BLC(2)

CCI Br

Alpha brass

avg. 1700 fps (10rnds)

.74 MOA 100yrds

I have a 20” Wilson Super Sniper barrel sitting here to be built.AR10 .308 20" Wilson Combat heavy barrel

168gr ELD-Match

44gr BLC(2)

CCI Br

Alpha brass

avg. 1700 fps (10rnds)

.74 MOA 100yrds

Assuming that’s a typo on the speed?

Good to hear the precision is GTG for the Wilson.

Aero Precision .308 Win w/ 24" X-caliber barrel, R+2" gas system

Norma brass

168gr SMK #2200

IMR 4895 (43.2 grain)

Federal GMM 210M

COAL: 2.815"

.500" at 100 yards

Coincidently, was ladder testing handloads for my Rem 700 w/ 24" Krieger barrel yesterday. This same recipe through the Rem 700 shot a .200" 3-round group.

Norma brass

168gr SMK #2200

IMR 4895 (43.2 grain)

Federal GMM 210M

COAL: 2.815"

.500" at 100 yards

Coincidently, was ladder testing handloads for my Rem 700 w/ 24" Krieger barrel yesterday. This same recipe through the Rem 700 shot a .200" 3-round group.

Reloaded Cartridge Neck Tension For .308 AR10

What neck tension are the rest of you running for your AR10 reloaded 308 cartridges? Previously my RCBS bushing resizing die with carbide expanding button was giving me 0.0015” to 0.002” neck tension, but I have moved to a Whidden non-bushing die and a 21stCentury 0.305” expander mandrel. This combination is giving me 0.003” neck tension.

What neck tension are the rest of you running for your AR10 reloaded 308 cartridges? Previously my RCBS bushing resizing die with carbide expanding button was giving me 0.0015” to 0.002” neck tension, but I have moved to a Whidden non-bushing die and a 21stCentury 0.305” expander mandrel. This combination is giving me 0.003” neck tension.

I have went to 0.002 on 223, 30 cal anything, and all 6.5.

No problems found.

Edit: Semiauto rounds get a slight crimp.

No problems found.

Edit: Semiauto rounds get a slight crimp.