Should I be concerned with shortened barrel life if I find a load at jam - 20 vs something in the 50 - 100 range. OR are the hotter loads going to affect the barrel life much more than the short jumps? Or both? I'm guessing the hotter loads.

I've loaded a few 108 ELDs at 33.4gr of Varget, Alpha OCD, 450s with 60 jump that gave respectable groups, but my MPA barrel is still new, less than 50 rds and I'm getting used to the MPA BA Comp chassis when my Vudoo sits in an ACC. I like the ACC better.

From what I've seen, the longer the jump, and the lower the charge/slower speed, the longer the barrel life.

But in the end, go with what shoots, because barrels, like tires, don't last forever, YOLO lol!

Seriously, though, I'm still figuring things out a little for myself... there seem to be 2 ways to go about it: you can either find the longest jump the gun likes and then park it there and run it (I've had 2 6CM barrels that I've run 100 thou off like this and they both basically shot the same and consistent for their whole

longer than usual lives), with a newer 6GT barrel, it shot great at 50 off all the way to 100 off, but due to the case and chamber being different/shorter than the 6CM barrels, I've been running it at 50 off and as the throat erodes it will back off and develop more jump "naturally".

That's why I mentioned the neck & bearing surface thing: using the exact same bullet, in 6CM, 100 off "looks better" meaning that the bullet isn't pushed back below where the shoulder starts, while in 6GT, somewhere ~60 thou off puts the bottom of the bullet below where the shoulder starts and 100 off would push the bullet a little too deep into the case for me... so I decided to leave the 6GT at 50 thou off. I haven't quite figured out if this neck/bearing surface relationship "is a thing" or just a coincidence yet, but it's been working out and I actually didn't notice it until after I'd already had the loads together (so I think it might be a thing lol).

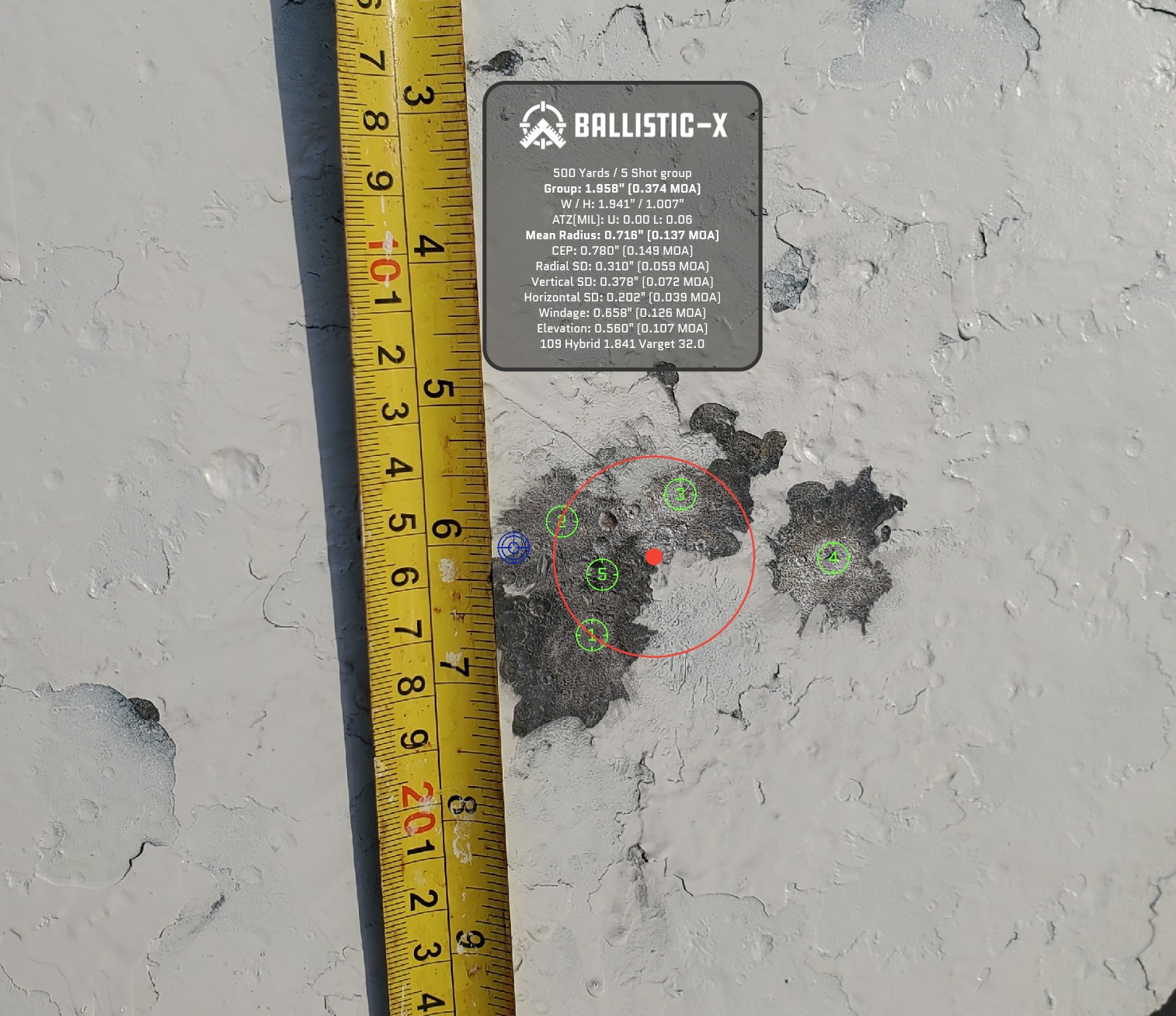

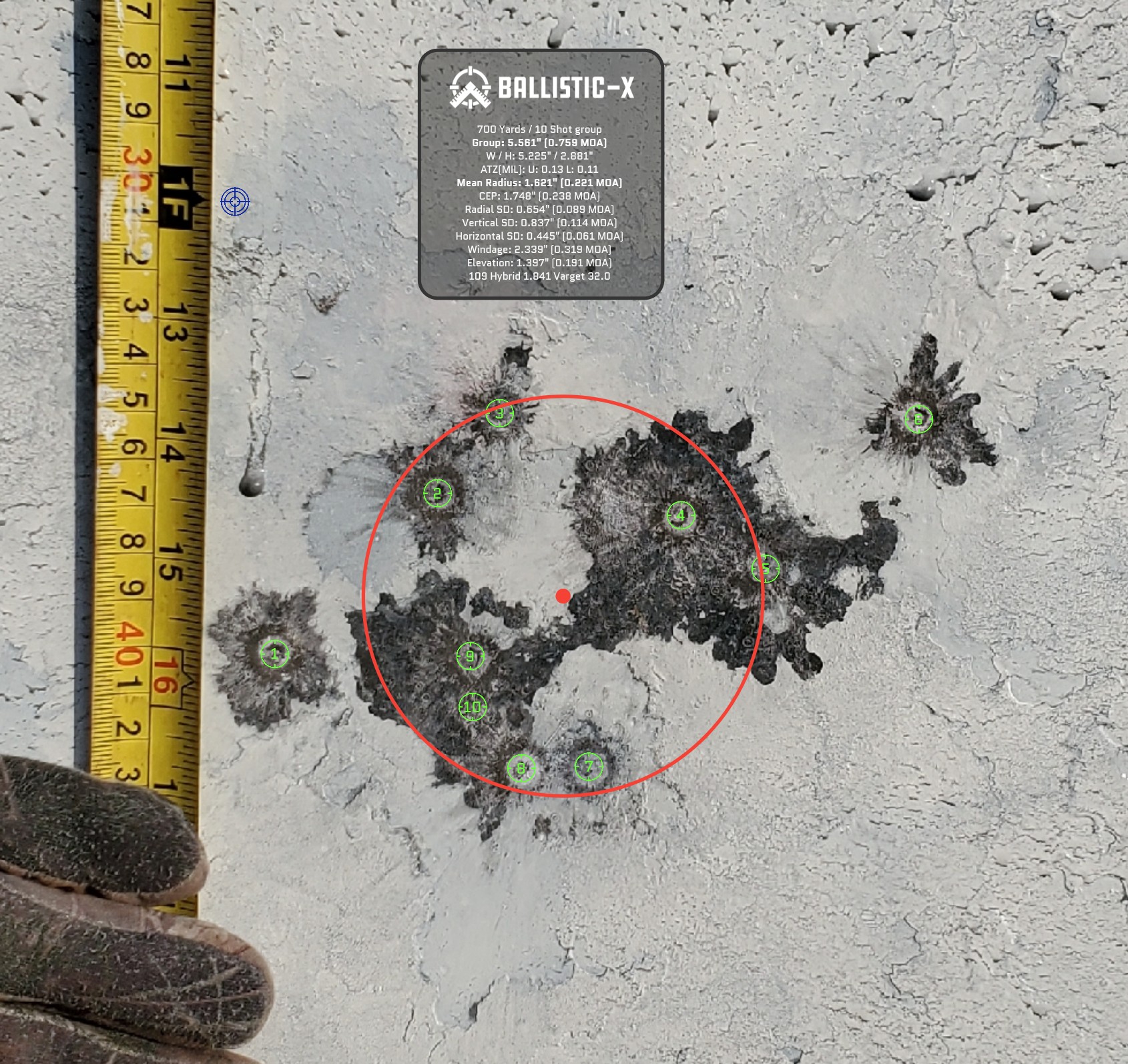

The pic tells the story: